Automated electroplating system for surface treatment of titanium and titanium alloys for medical technology

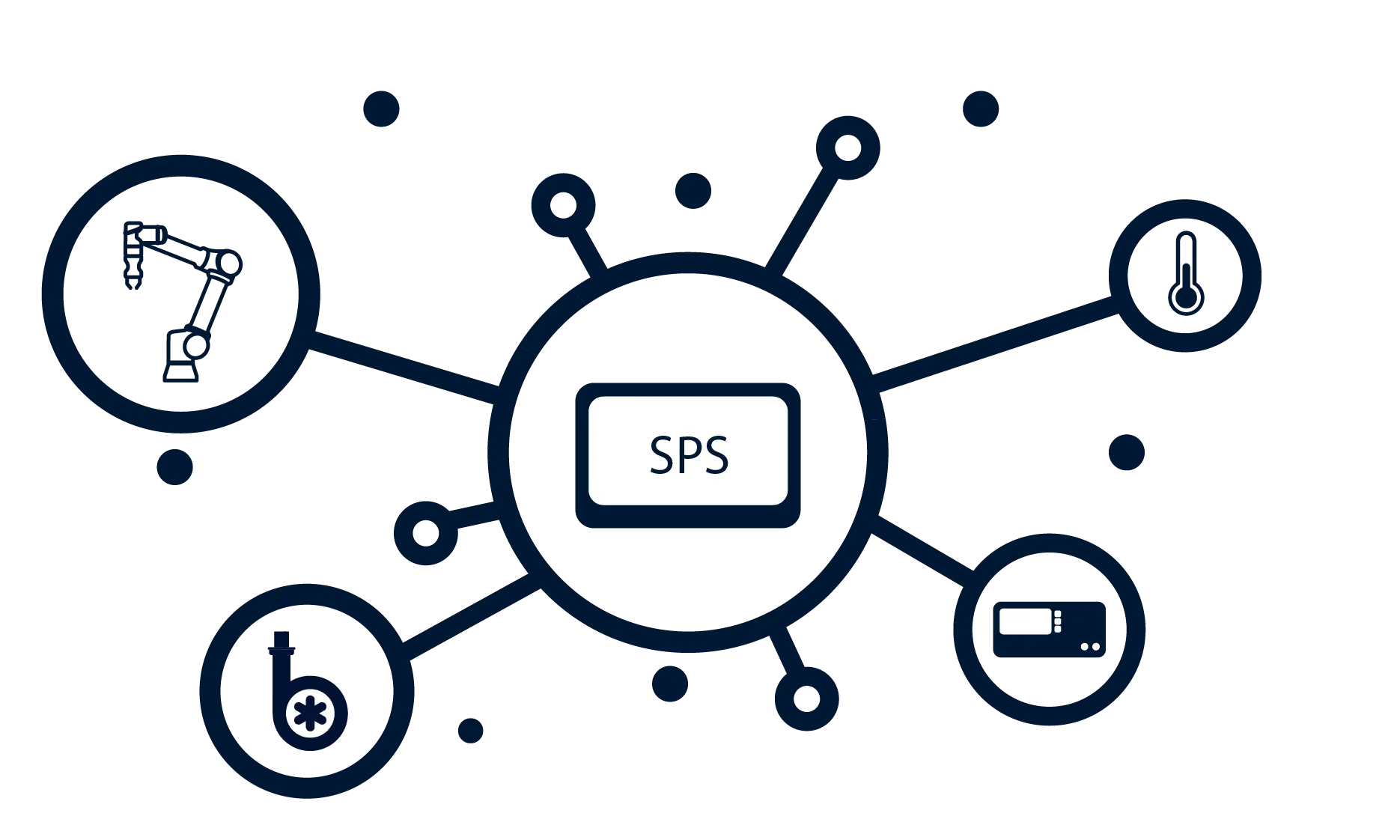

The COMPACTA PLC optimizes and automates chemical and electrochemical process sequences in the

electroplating technology. It offers numerous control options & setting parameters for a customer-specific process sequence. Thanks to automation, consistent surface results can be achieved on a recurring basis.

On our systems, you can implement a wide range of processes that are important for medical technology. Whether electropolishing for stents or anodizing of medical components for better visibility.

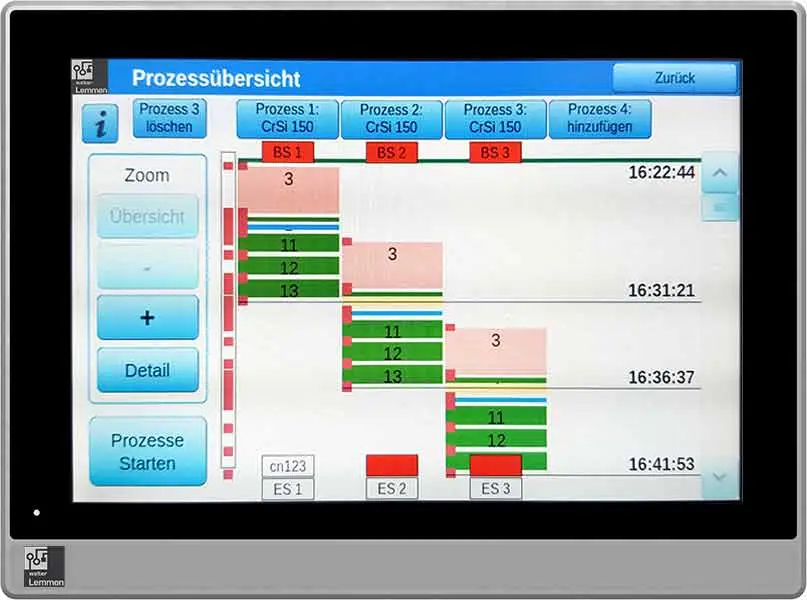

Realize several processes simultaneously on our systems.

With the COMPACTA PLC electroplating line, upward and downward movements can be individually programmed and executed on the linear traversing system. The process sequences are carried out sequentially or optionally in parallel operation.

The rope system developed in-house for transporting the product carriers is made of chemical-resistant polypropylene and is therefore suitable for all chemical and electrochemical electrolyte applications.

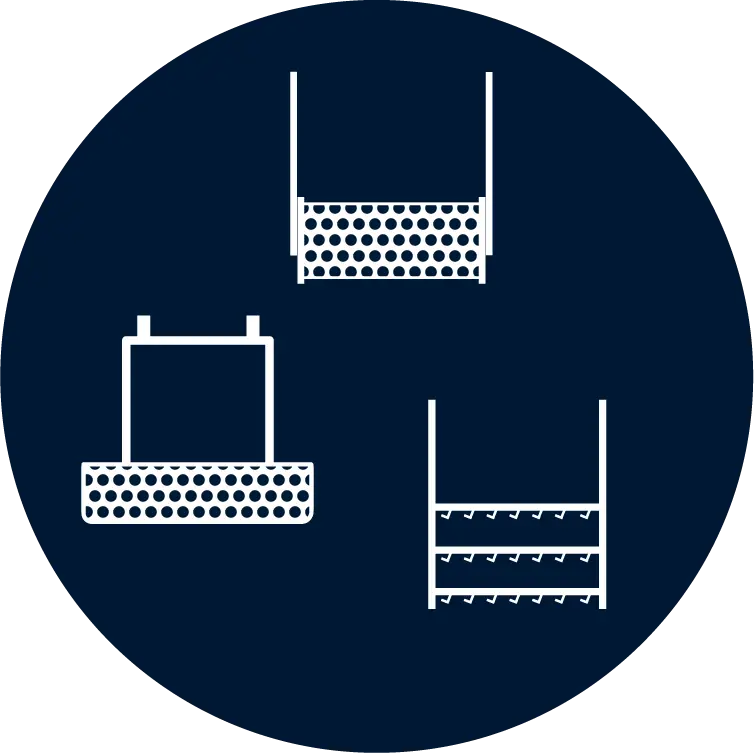

The COMPACTA SPS is multifunctional and can be used for drum, basket and rack goods. The maximum payload per container is approx. 10 kg. The basin volume and other equipment features can be customized.

Versions:

Standard tray design:

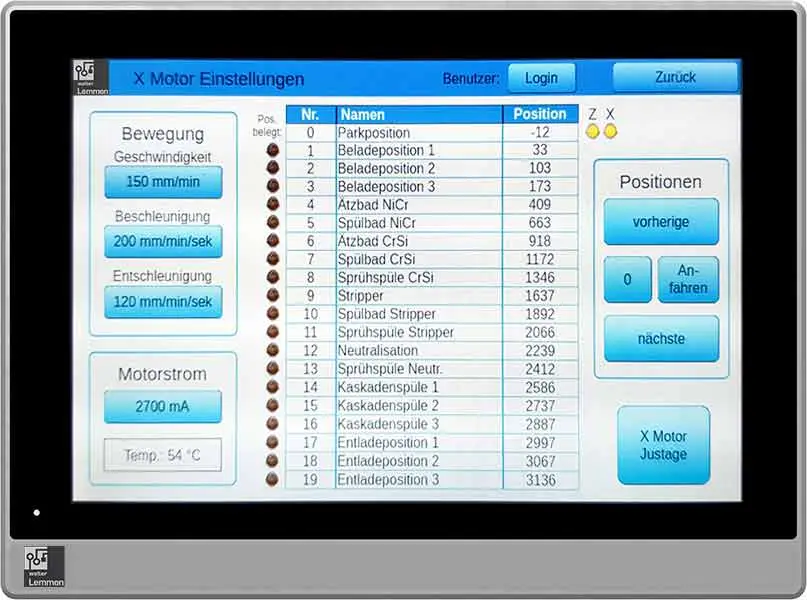

The following bath parameters can be individually programmed using the PLC control:

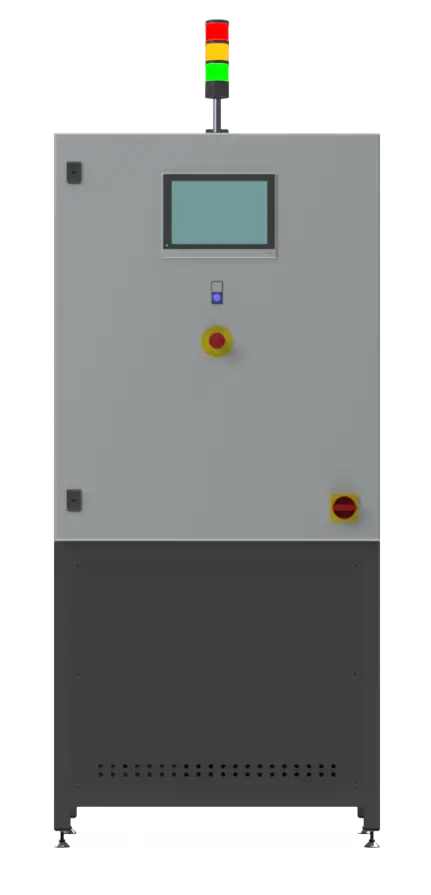

The external control cabinet serves as the central control unit. Important process parameters such as temperature, current, bath movement, etc. are monitored and regulated in real time via the PLC control. The switch cabinet thus ensures precise automation of the electroplating processes and guarantees stable and efficient operation of the entire system. Thanks to the PLC technology, errors can be quickly identified and rectified, ensuring the production quality and operational reliability of the system at all times.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

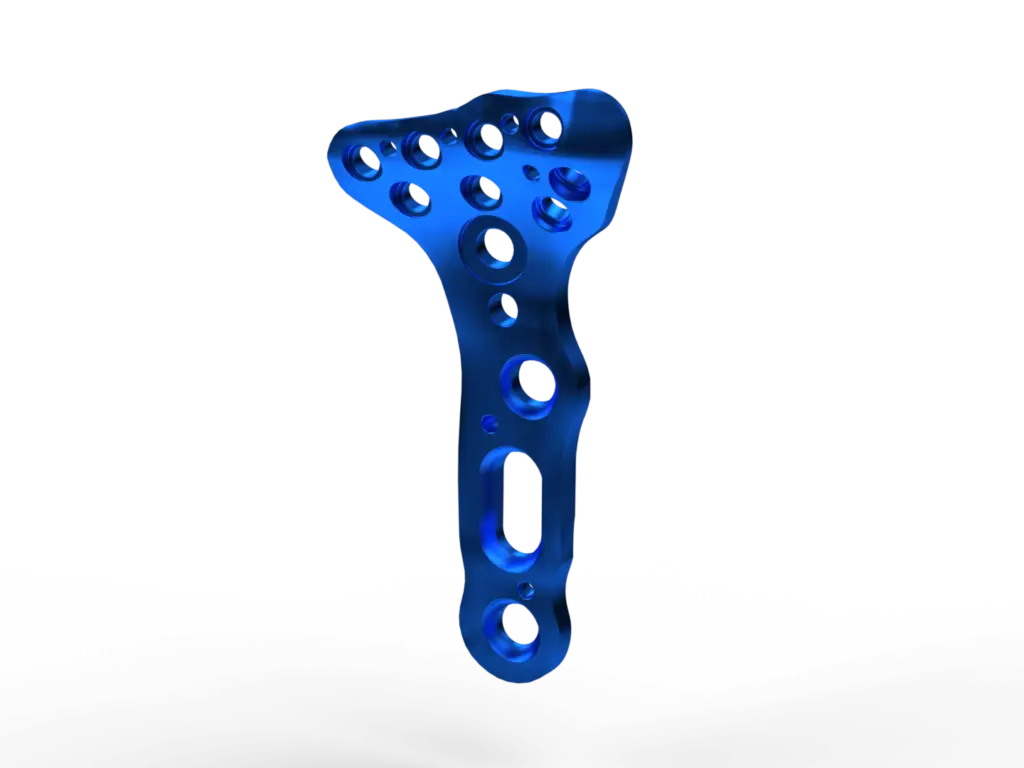

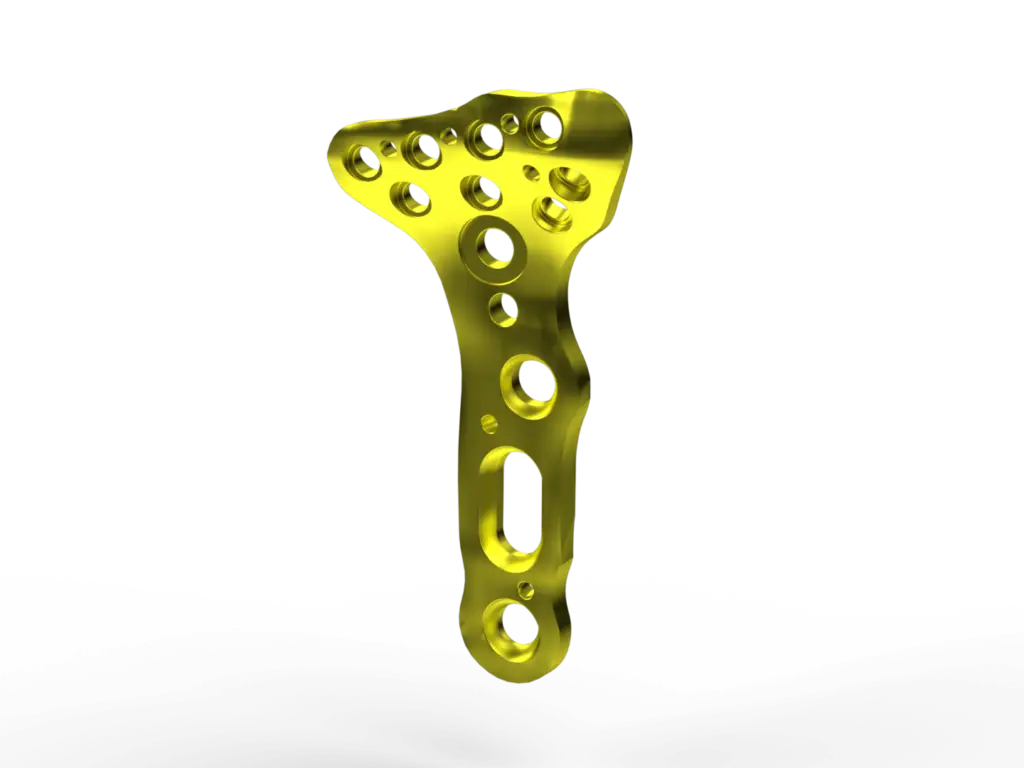

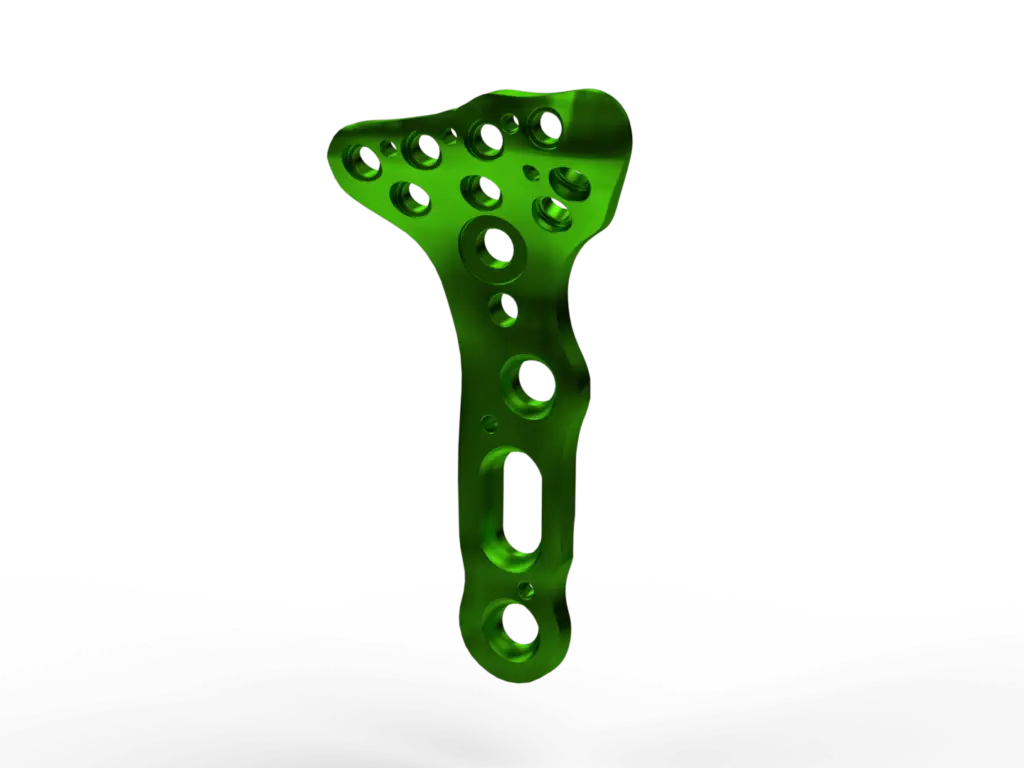

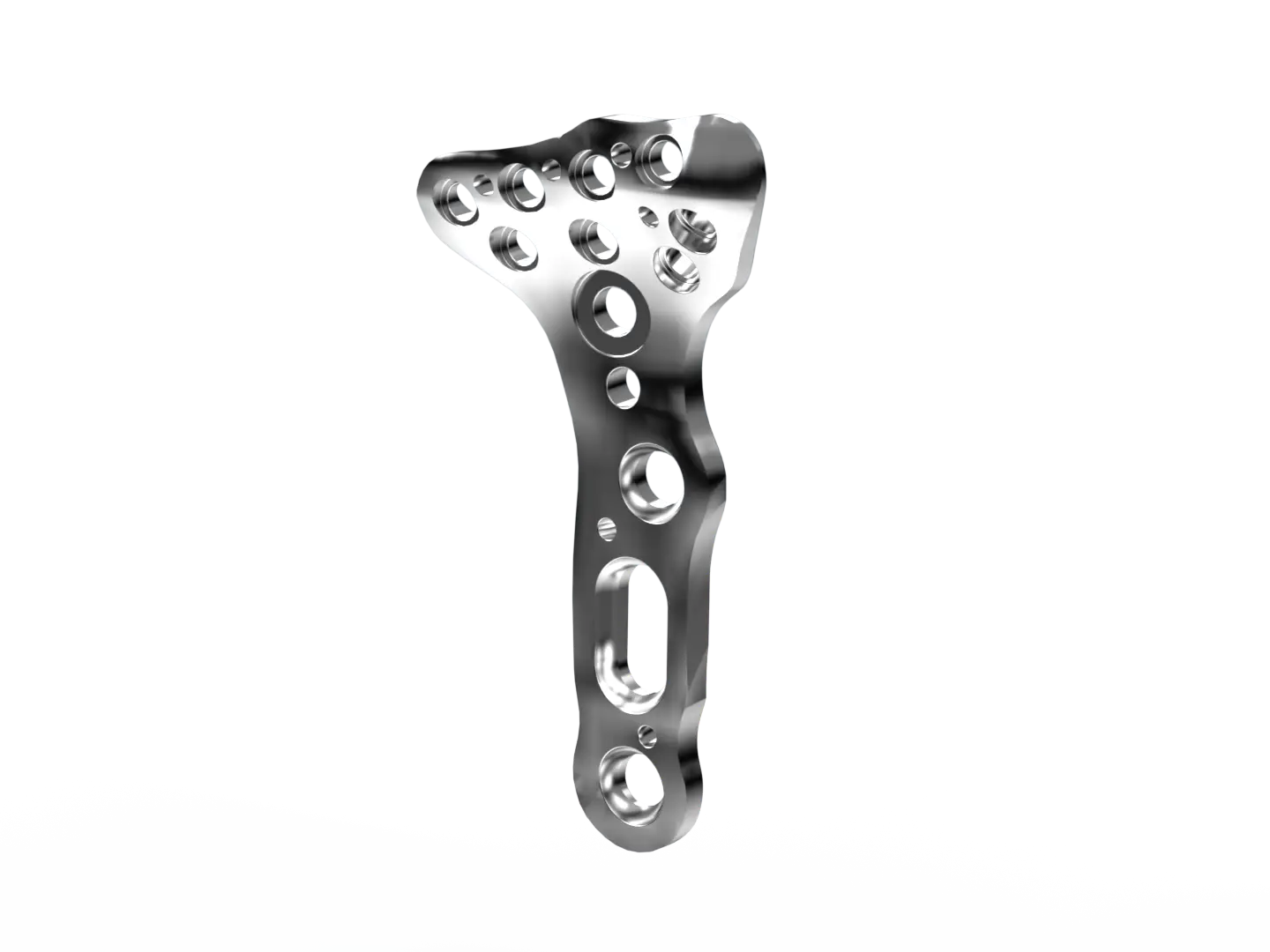

Medical parts or components made of titanium or titanium alloys are electrochemically anodized with special aqueous electrolytes. The result is a thin, firmly adhering titanium oxide layer that appears colored due to the superimposition of light waves (interference). The color palette of type III anodized surfaces ranges from titanium grey, blue, yellow, magenta to green. The main purpose of anodizing medical parts and components is to improve identification and corrosion protection. The titanium oxide layer has very good electrical insulation and biocompatibility

In addition to colour anodizing, grey anodizing (acidic or alkaline) can also be carried out in the systems. Type II grey anodizing is preferably used for bone plates, bone screws and bone implants. The process produces even thicker coatings and serves to improve corrosion and wear resistance.

Electrochemical polishing (electropolishing) and deburring of stainless steel significantly improves the properties of the metallic surface, which has a positive effect on the durability of the individual components. Electropolishing is an electrochemical process for surface removal. The removal is carried out with special aqueous solutions using electricity in the micro range and produces a smooth and shiny surface.

Your contact to us

Sie sehen gerade einen Platzhalterinhalt von rapidmail. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenMarketing & Sales

You are currently viewing a placeholder content from Accessibility Widget. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information