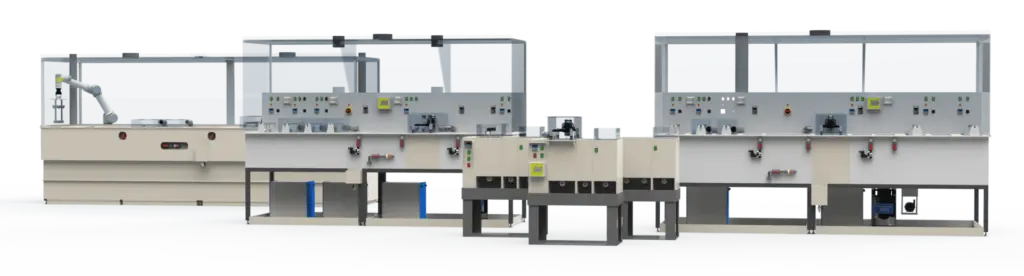

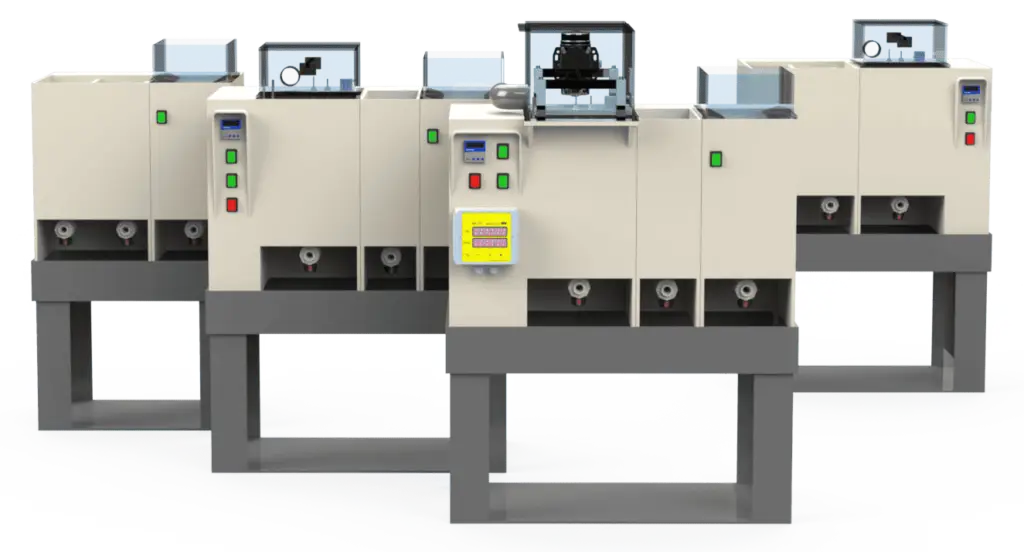

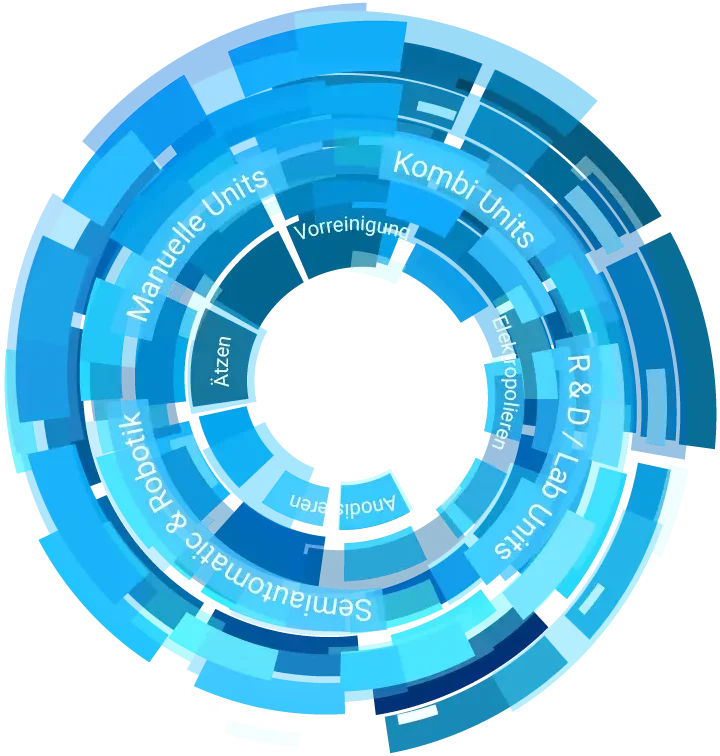

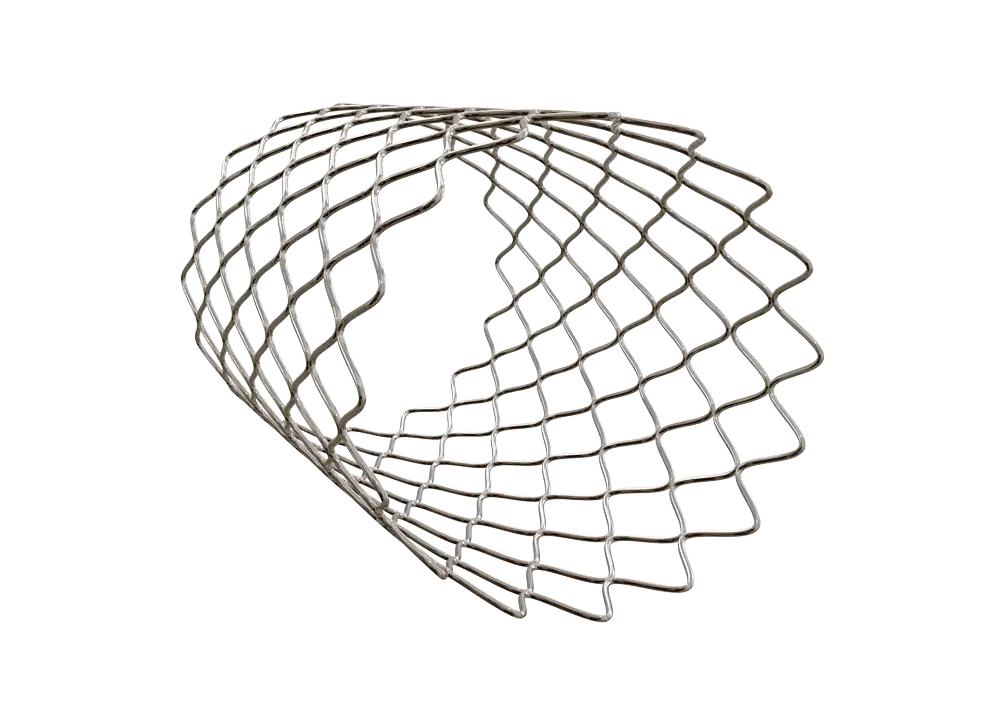

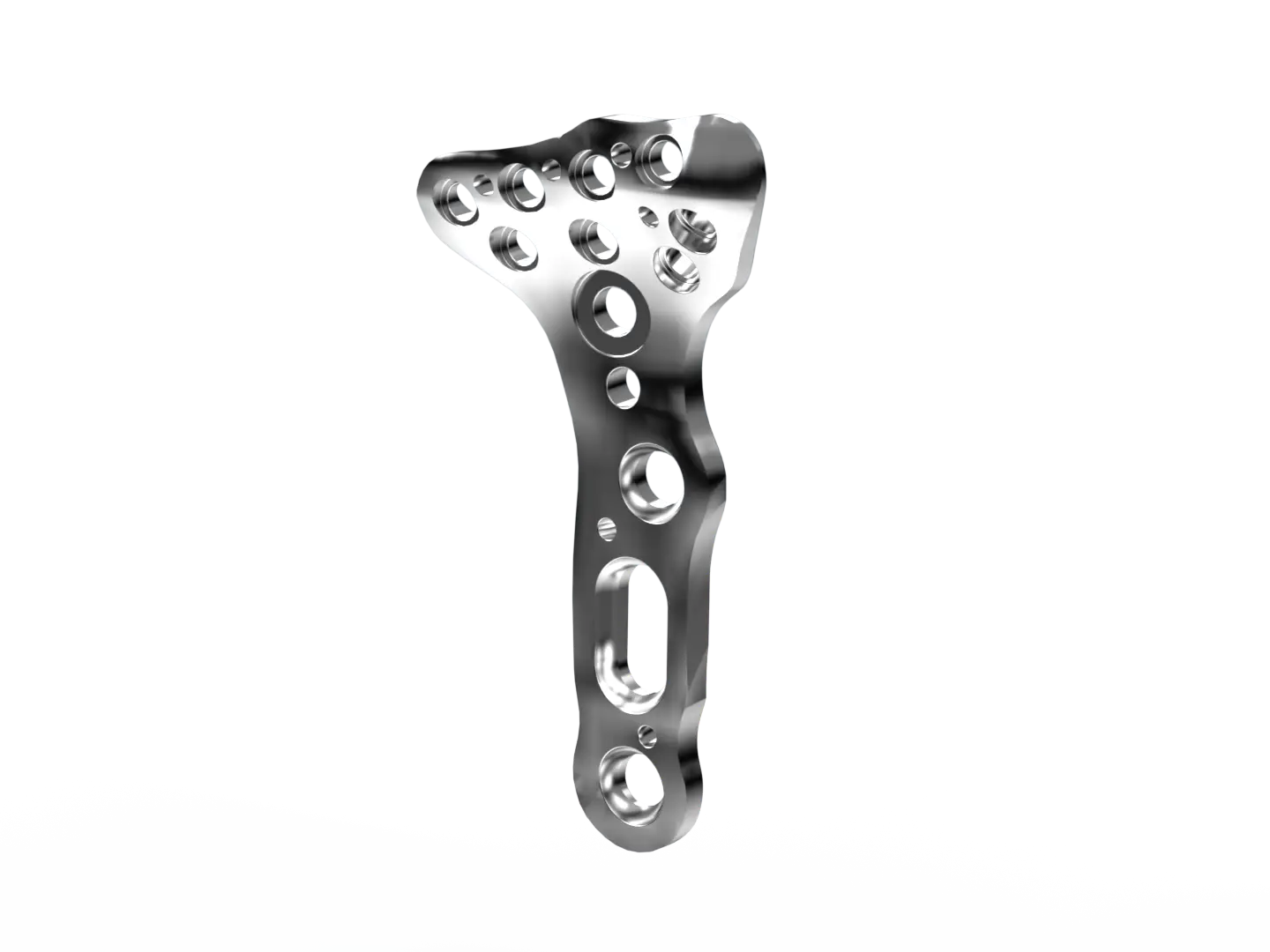

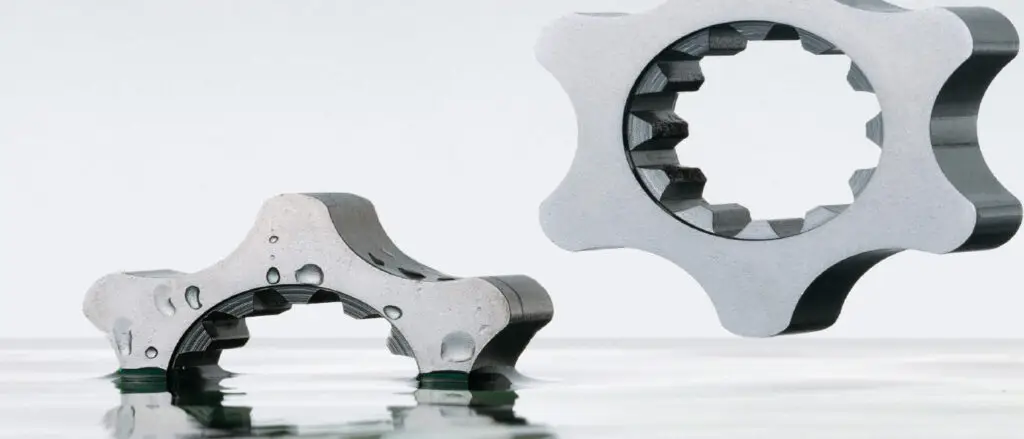

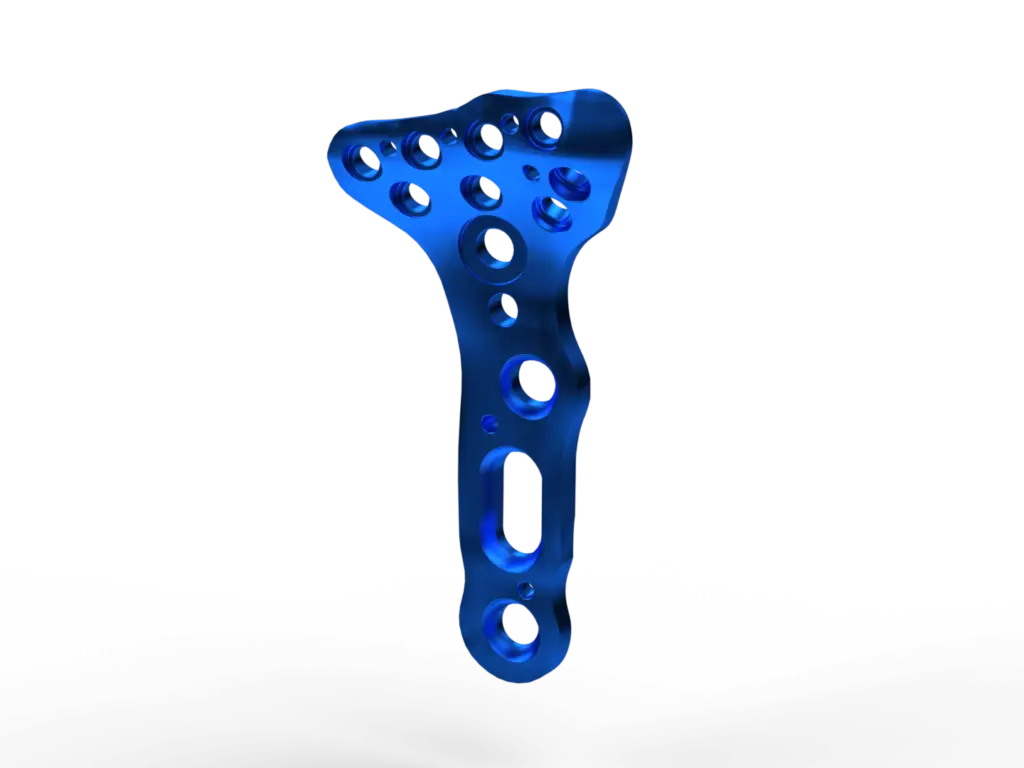

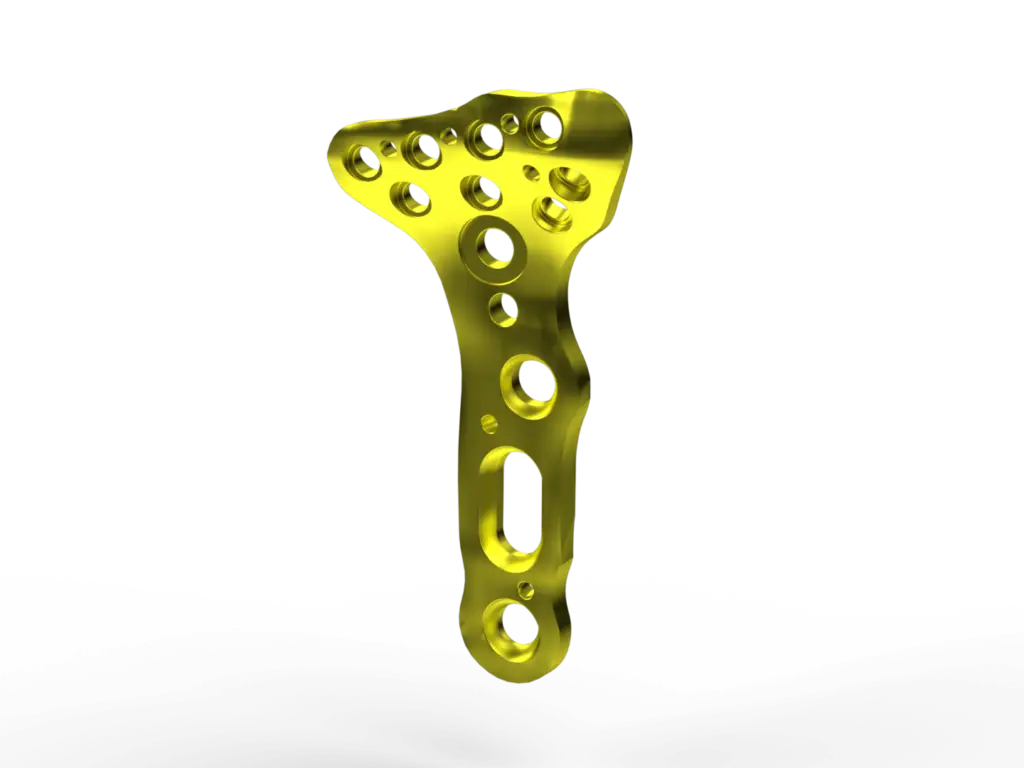

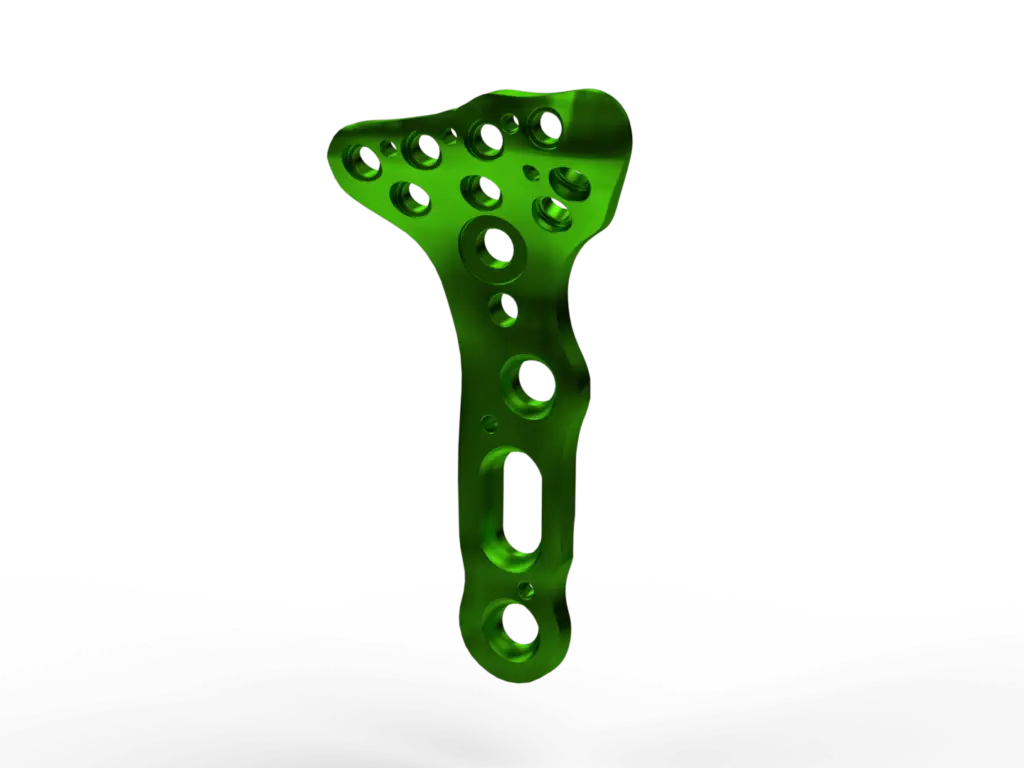

Our electroplating systems for medical technology enable high-precision surface coating of sensitive components such as implants, surgical instruments and other medical components. Using state-of-the-art process technology, we ensure that the coatings meet the highest requirements for biocompatibility, corrosion resistance and functionality. The systems are flexibly configurable and meet the strictest hygiene and quality standards – for safe and long-lasting use in medical environments.