The multilayer presses of the MLP-L series are devices for the production of multilayer PCBs (multilayers) for prototype and small series production.

The system can be used to press together multi-layer circuits made from different PCB materials. Uniform hydraulic pressure distribution combined with a vacuum frame system and freely programmable preheating and process temperatures ensure optimum material bonding across the entire working surface.

With separately controlled, electrically heated press plates and a hydraulic system, the MLP-L model series offers high functionality for a wide range of manufacturing processes.

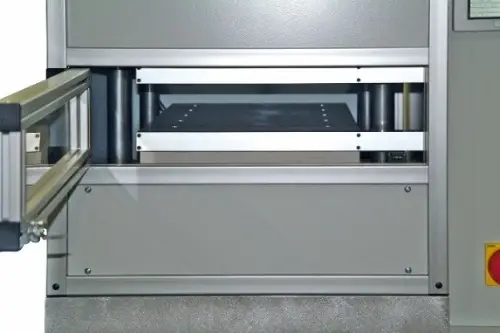

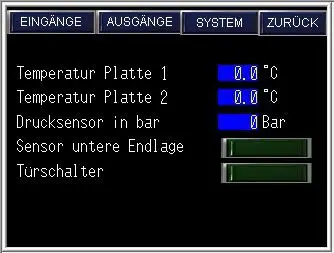

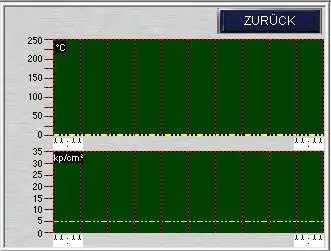

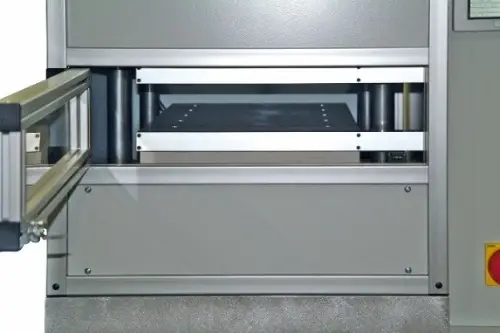

The MLP-L system is loaded with pressing tools from the front. It is operated via a graphic touchscreen panel. All process sequences are carried out automatically and managed.

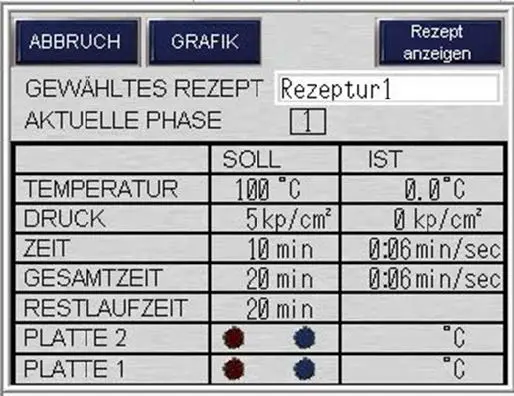

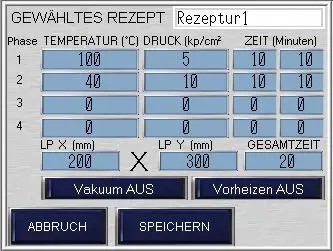

The touchscreen panel displays the operating status, programme stages and remaining times in real time. Pressure control is infinitely variable via a hydraulic system using a proportional valve and pressure transducer. The system can be cooled by air or, optionally, by water.

Loading side with tilting elements in the heating plate, enabling contact-free removal of the pressing tool during the loading process.

Multilayer press

MLP-L-3040 VAC

Vacuum

optional

Pressing force

230 kN

Number of heating plates

2

Heating plate size

460 x 350 mm

Max. laminating area

400 x 300 mm

Surface load

approx. 1,000 kg/m²

Number of floors

1

Light width

80 mm

Weight

approx. 500 kg

Dimensions (L x W x H)

approx. 805 x 650 x 1,550 mm

Heating

Max. Heating temperature

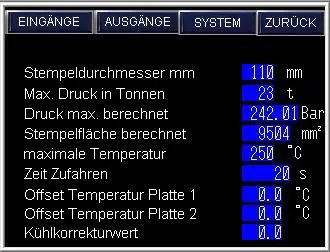

250 °C

Max. Heating temperature with vacuum

200 °C

Process temperature

Freely programmable

Preheating temperature

Freely programmable

Heating time (40 °C to 175 °C, uncoated)

approx. 25 min

Power consumption

Heating plate 1

2.5 kW

Heating plate 2

2.5 kW

Hydraulics

1.5 kW

Vacuum

0.7 kW

Total energy requirement

approx. 7.5 kW

Total energy requirement with vacuum

approx. 8.3 kW

Mains connection

3 x 400 V / 50 Hz

Rated current

13,2 A

Nominal current with vacuum

14,2 A

Protection

16 A

Cooling

Cooling time

Freely programmable

Cooling system

Air supply

optional: water cooling

Cooling water quantity per pressing cycle (option)

approx. 100 l

Available accessories

Starter package, consisting of:

(optional for model MLP-L 3040 VAC)

Vacuum: < 0 20 mbar

Pump-out time: > 30 sec

The vacuum is generated via the vacuum frame. Vacuum generation and decompression are performed by the control system.

Your contact to us

You are currently seeing a placeholder content of rapidmail. To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More informationMarketing & Sales

You are currently viewing a placeholder content from Accessibility widget. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information