Specification

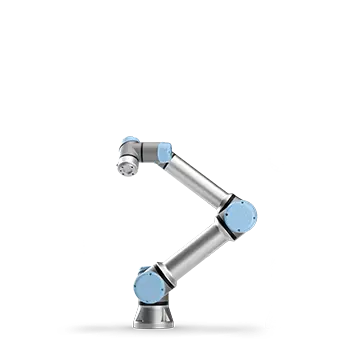

UE 3

UE 5

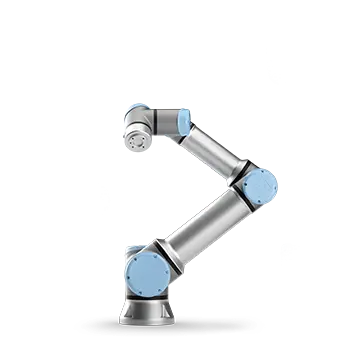

UE 16

UE 10

Load capacity

3 kg

5 kg

16 kg

12.5 kg

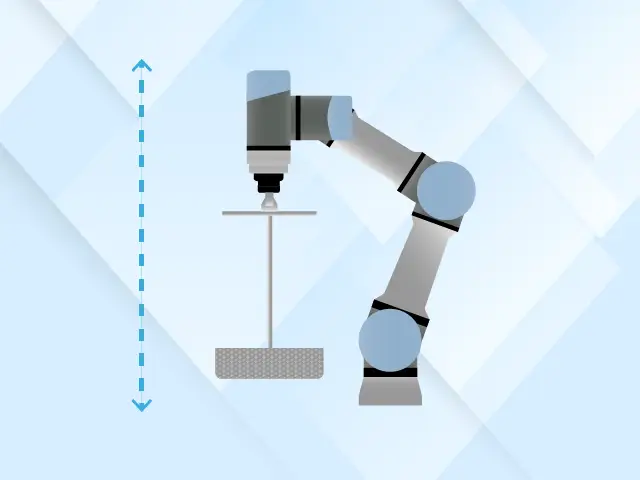

Range

500 mm

850 mm

900 mm

1300 mm

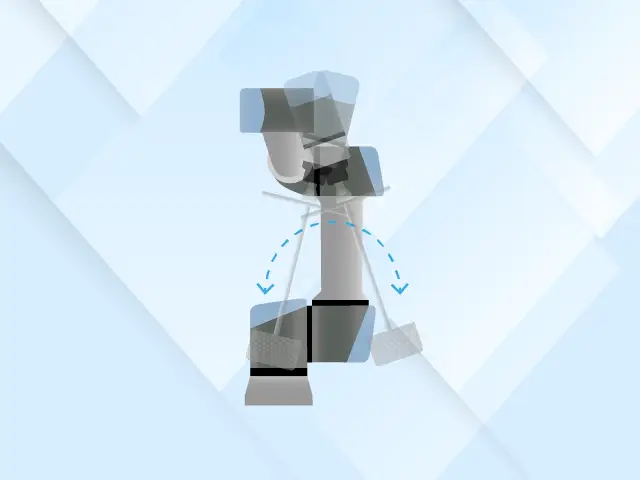

Degrees of freedom

6 rotating joints

Floor space

128 mm

149 mm

190 mm

190 mm

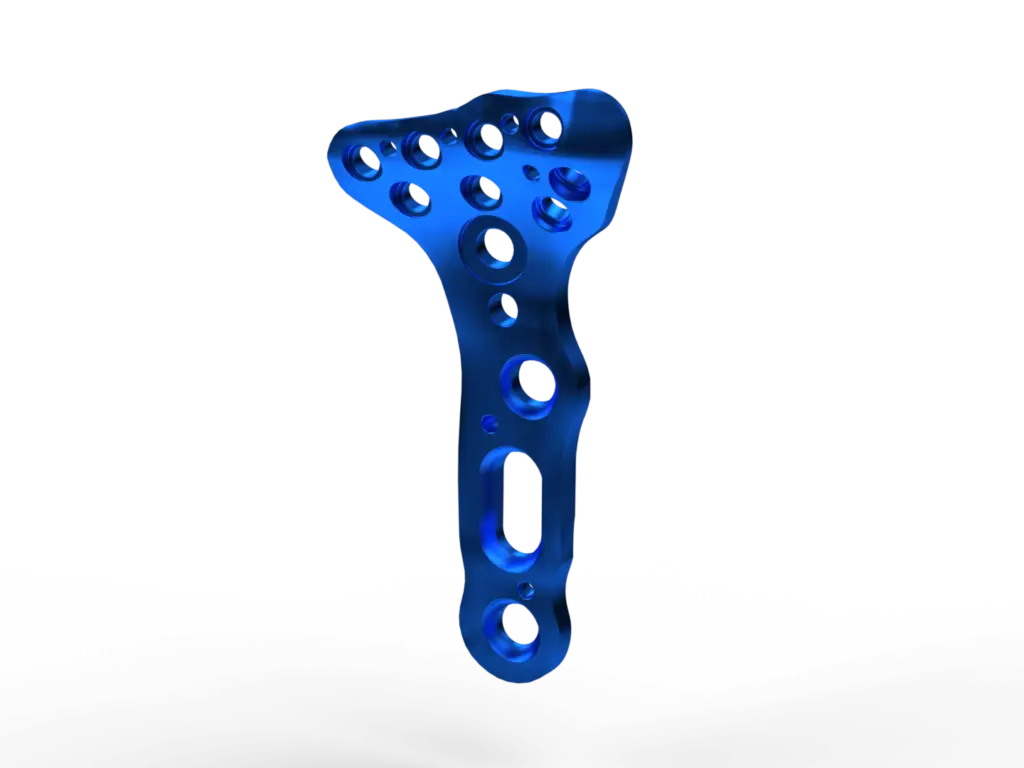

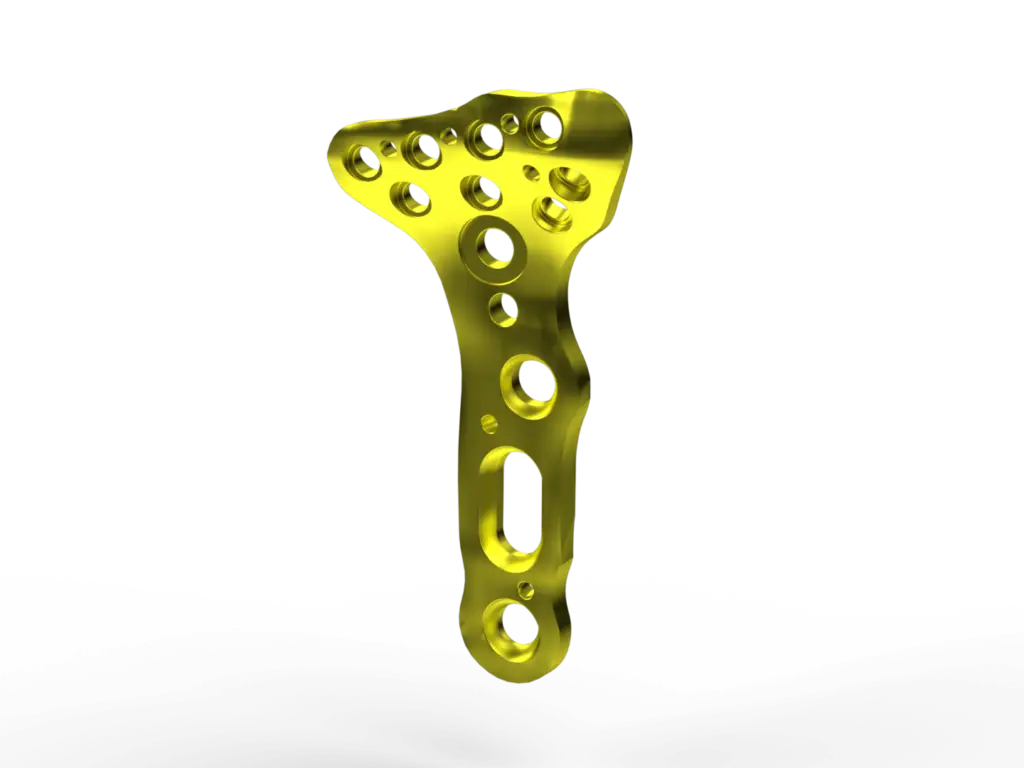

Material

Aluminum, plastic, steel

Weight

11.2 kg

20.6 kg

33.1 kg

33.5 kg

Power consumption

300 W

570 W

615 W

585 W

Connection type

M8 | M8 8-pin

Ambient temperature

0-50°C

IP classification

IP54

Moisture

90% RH (non-condensing)

Cleanroom class ISO 14644-1

5