Small electroplating system for colouring (anodizing) parts made of titanium or titanium alloys

The standard tanks with a tank volume of 5 liters, 15 and 25 liters are designed for operation at high voltages, CE-compliant with safety lid and functionally fast discharge after switching off.

As the shade and intensity of the coloration achieved depends crucially on the correct pre-treatment of the workpieces, the parts should be ultrasonically cleaned and degreased.

Output power: max. 12000 Watt

Output current: max. 60A (at 20V)

Output voltage: max. 600V (at 3A)

DATA SHEET RECTIFIER |

Output power: max. 750 Watt

Output current: max. 60A (at 12V)

Output voltage: max. 250V (at 3A)

|

DATA SHEET RECTIFIER |

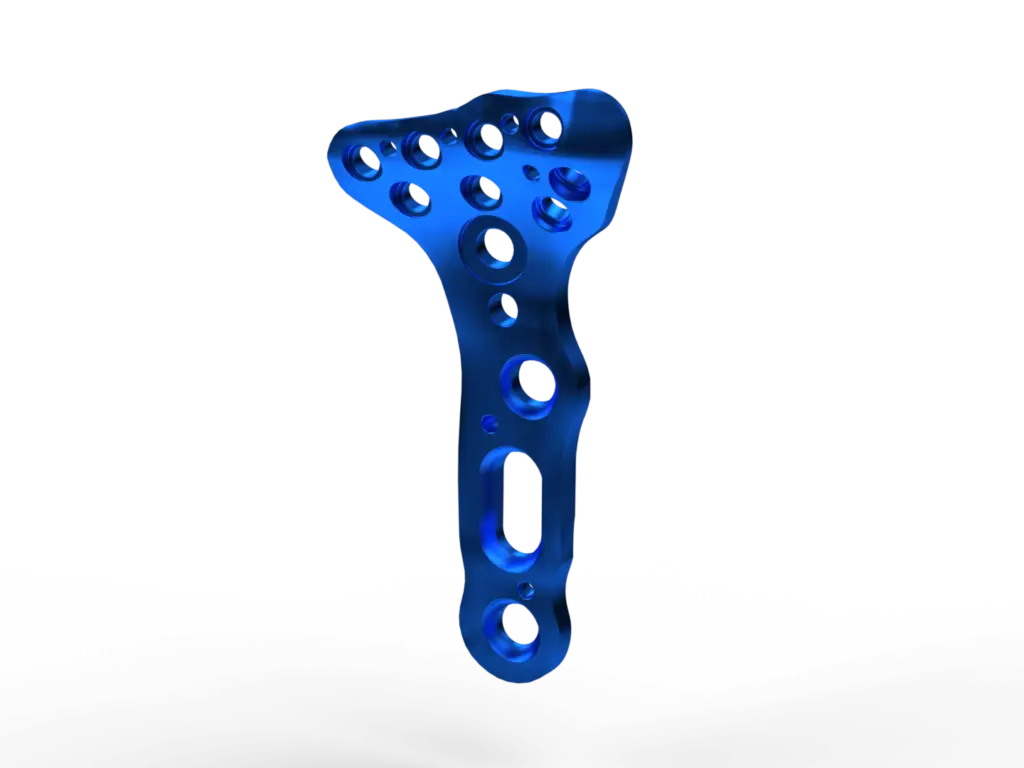

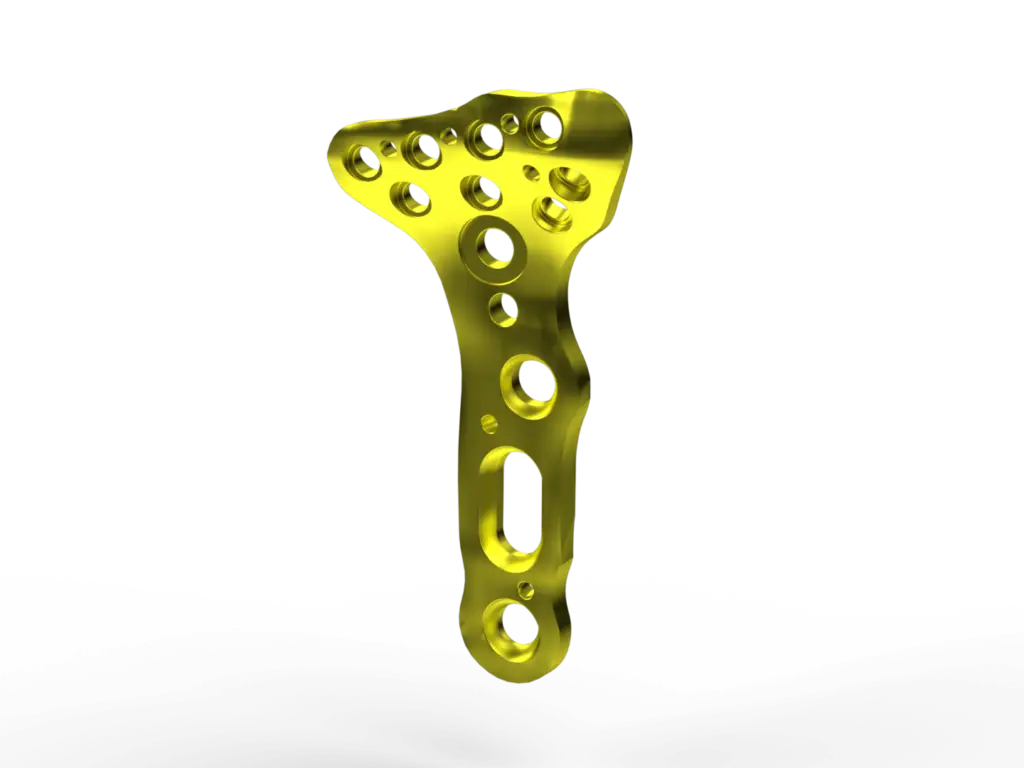

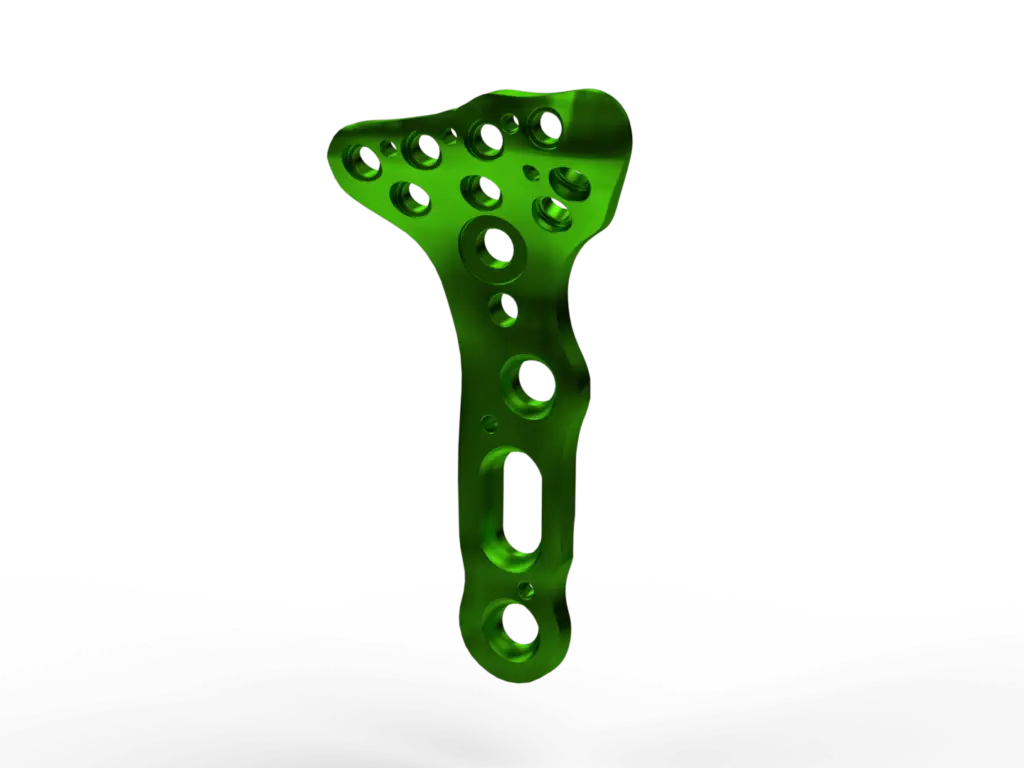

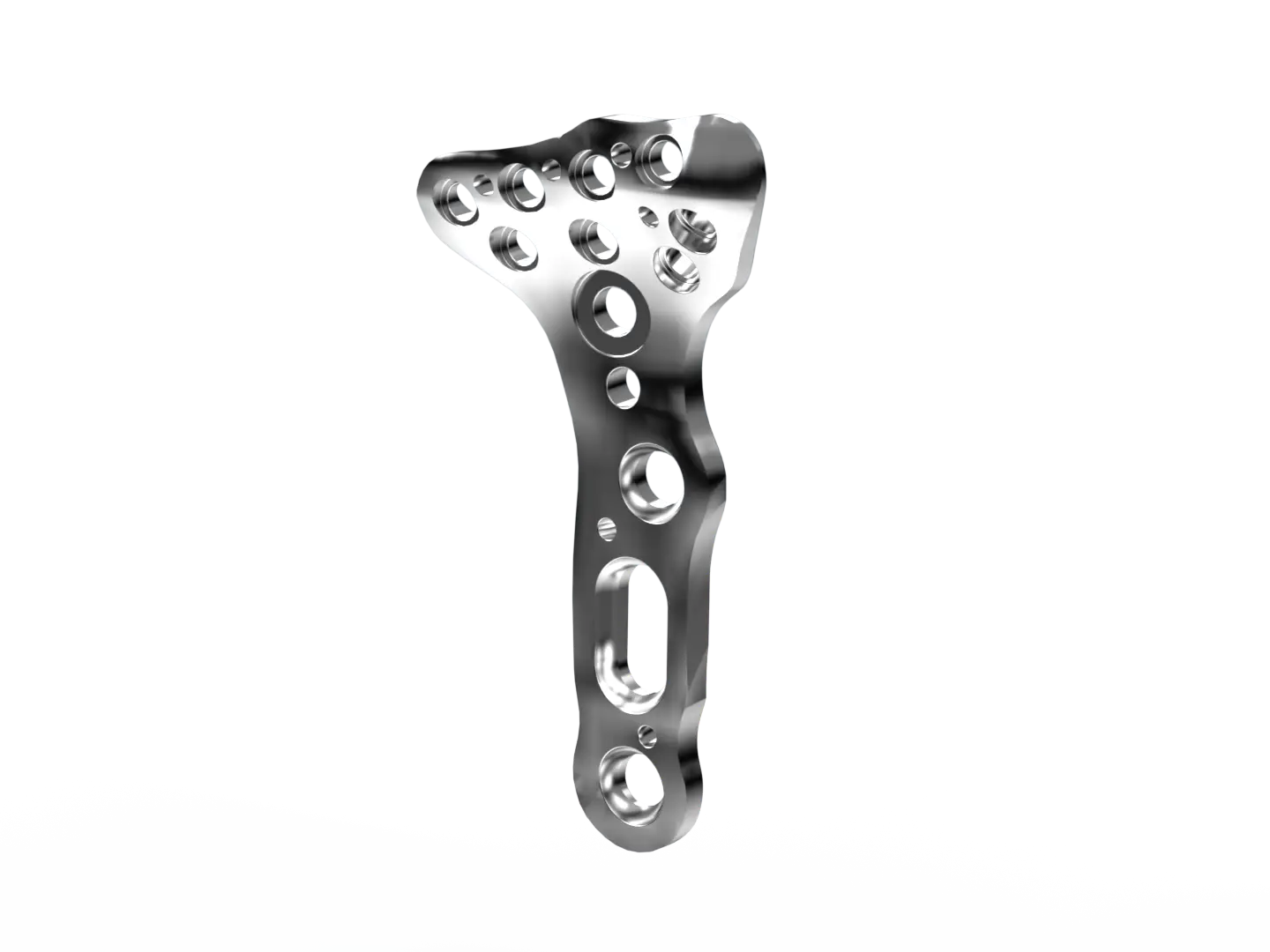

Medical parts or components made of titanium or titanium alloys are electrochemically anodized with special aqueous electrolytes. The result is a thin, firmly adhering titanium oxide layer that appears colored due to the superimposition of light waves (interference). The color palette of type III anodized surfaces ranges from titanium grey, blue, yellow, magenta to green. The main purpose of anodizing medical parts and components is to improve identification and corrosion protection. The titanium oxide layer has very good electrical insulation and biocompatibility

In addition to colour anodizing, grey anodizing (acidic or alkaline) can also be carried out in the systems. Type II grey anodizing is preferably used for bone plates, bone screws and bone implants. The process produces even thicker coatings and serves to improve corrosion and wear resistance.

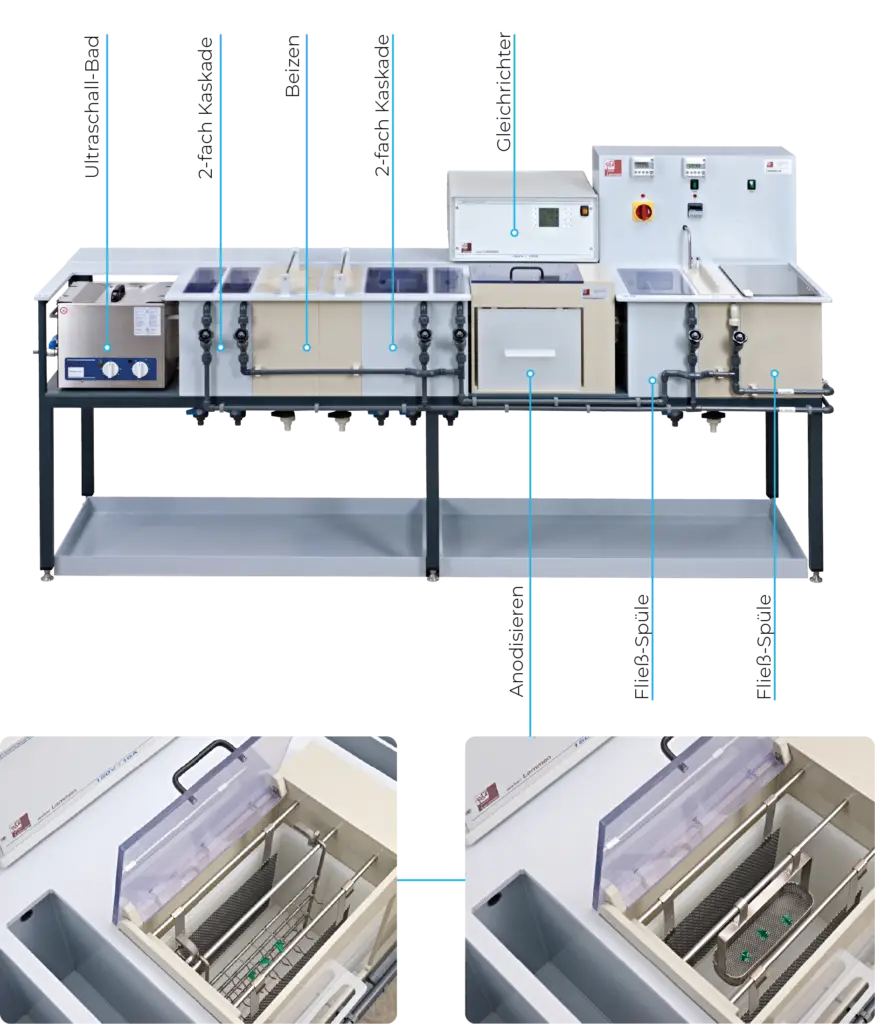

Pre- and post-treatment tanks in combination with small electroplating system for anodizing, with ultrasonic device, pre-treatment, pickling, dyeing, drying. Complete systems that cover the entire titanium coloring process are also offered as special solutions:

System structure (basic module):

We plan, develop and construct manual or automated units according to your individual surface process.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Your contact to us

Sie sehen gerade einen Platzhalterinhalt von rapidmail. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenMarketing & Sales