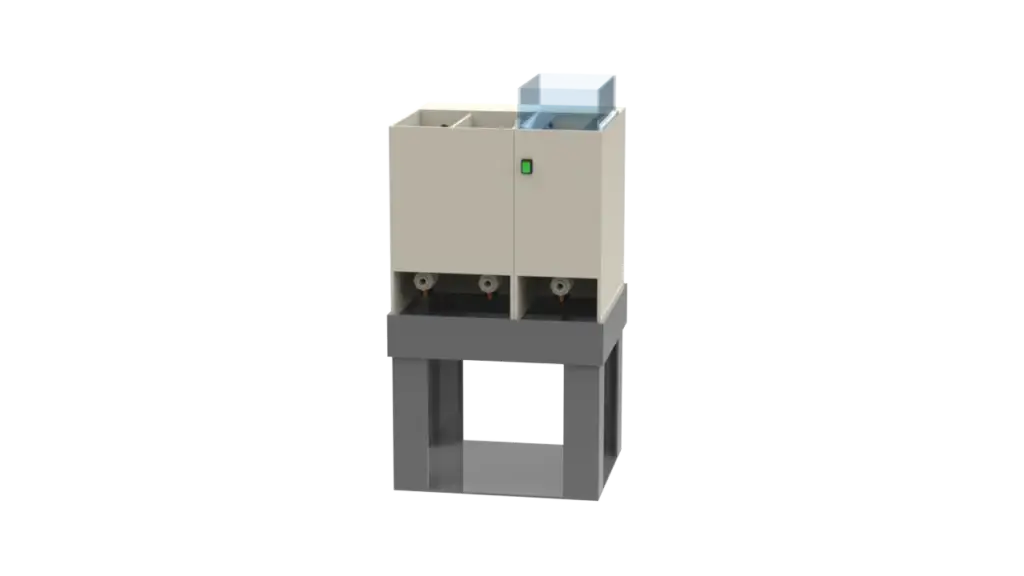

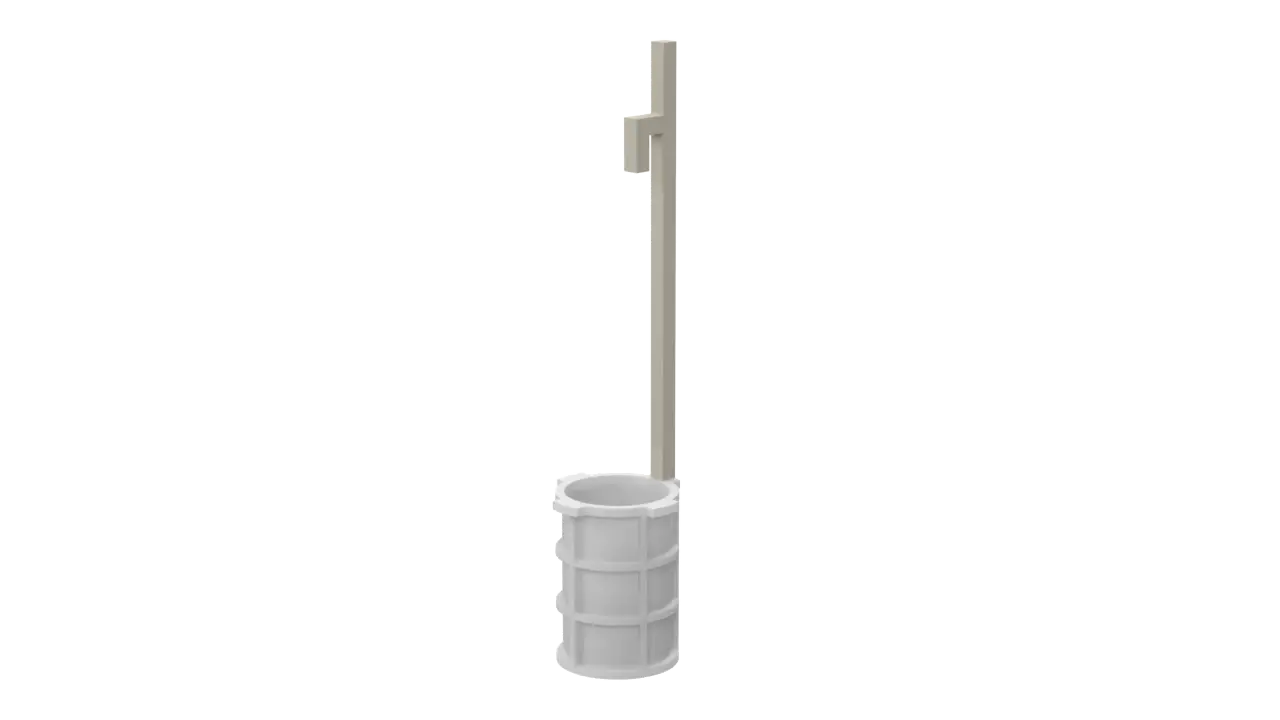

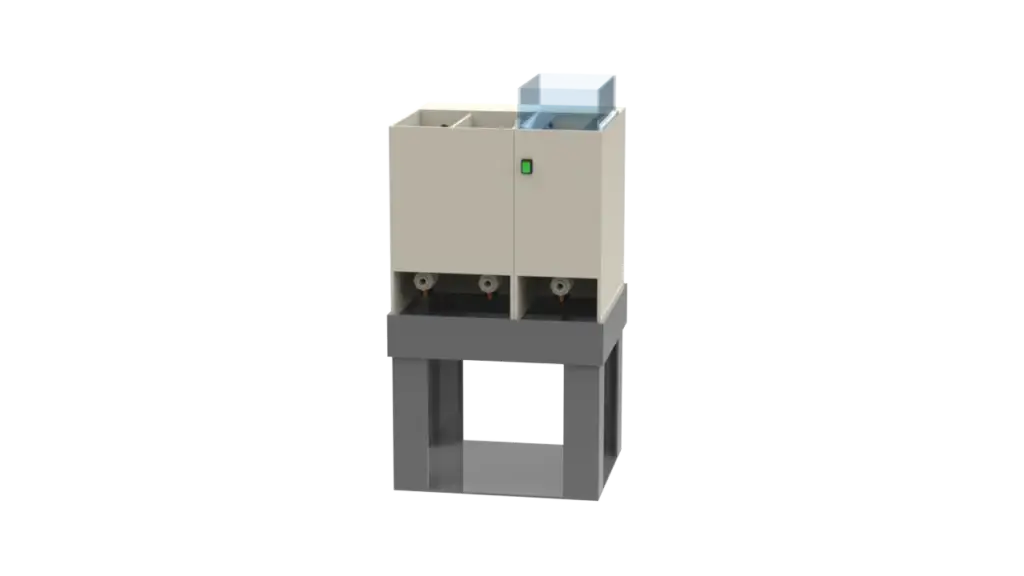

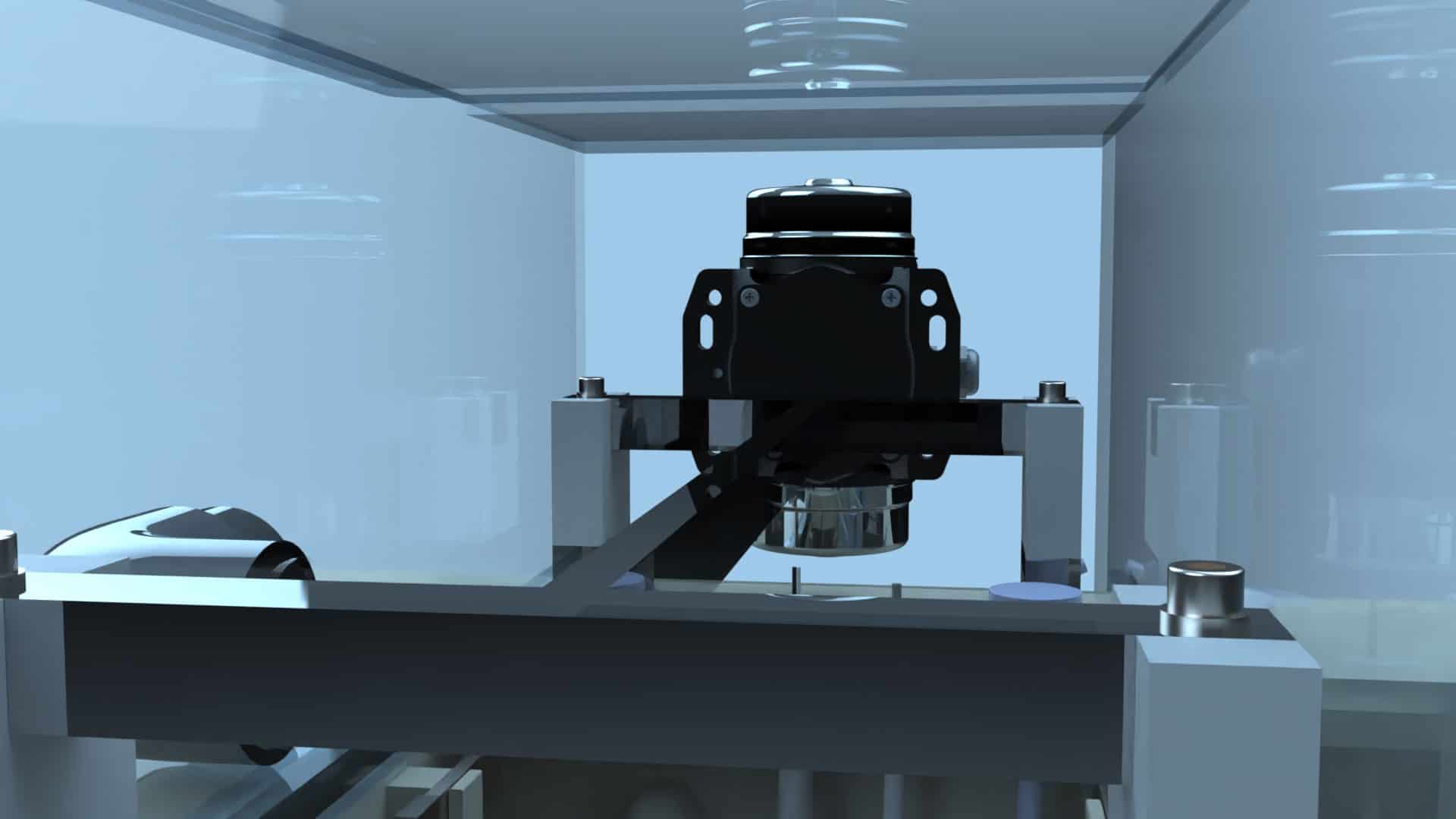

Titanium colouring system for colour anodizing type III and grey anodizing type II of components made of titanium and titanium alloys for medical technology. The modular system design enables adaptation to your process requirements and surfaces. The module consists of an anodising tank with control panel, cover with extraction nozzle and release contact. Various optional tank equipment in combination with additional rinsing units, base frame and drip tray guarantee optimum surface results.

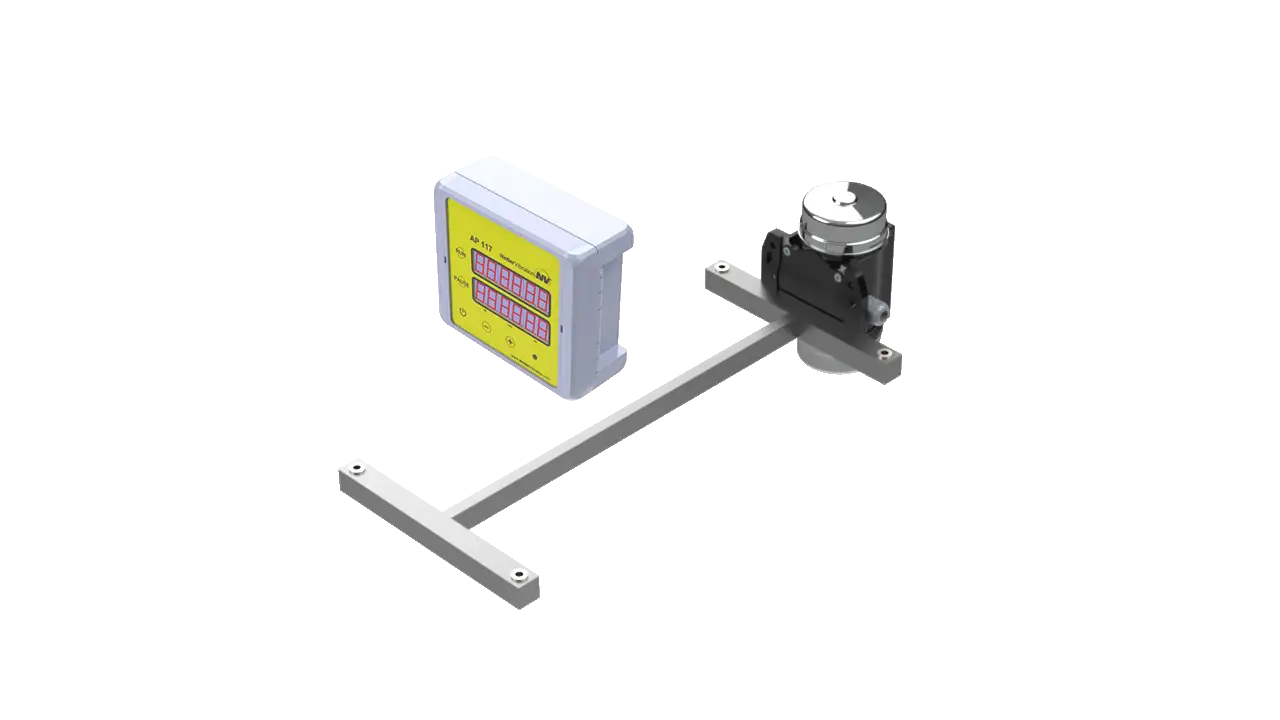

Pause control

The second-accurate working time management allows freely selectable intervals for the motion system in the anodising module. Thanks to the precisely adjustable interval operation, work and cycle break times for rack and basket vibration can be defined and digitally documented with process accuracy.

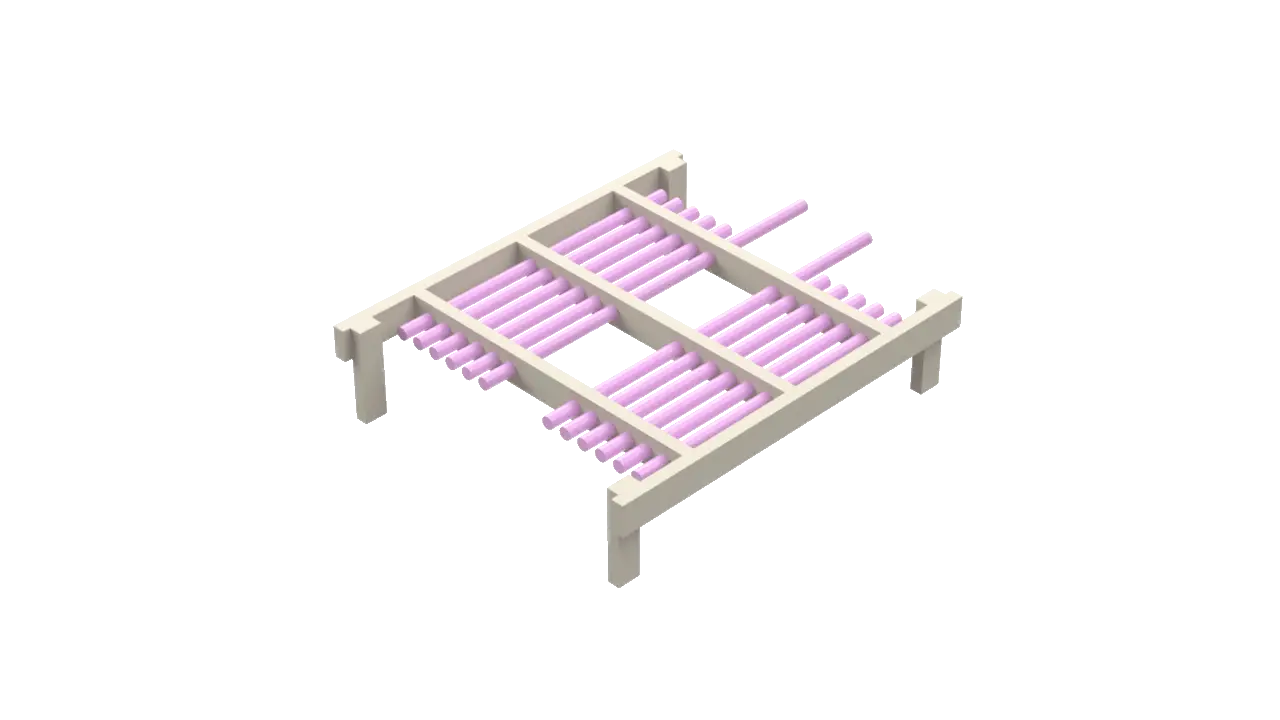

Individual production & mass production

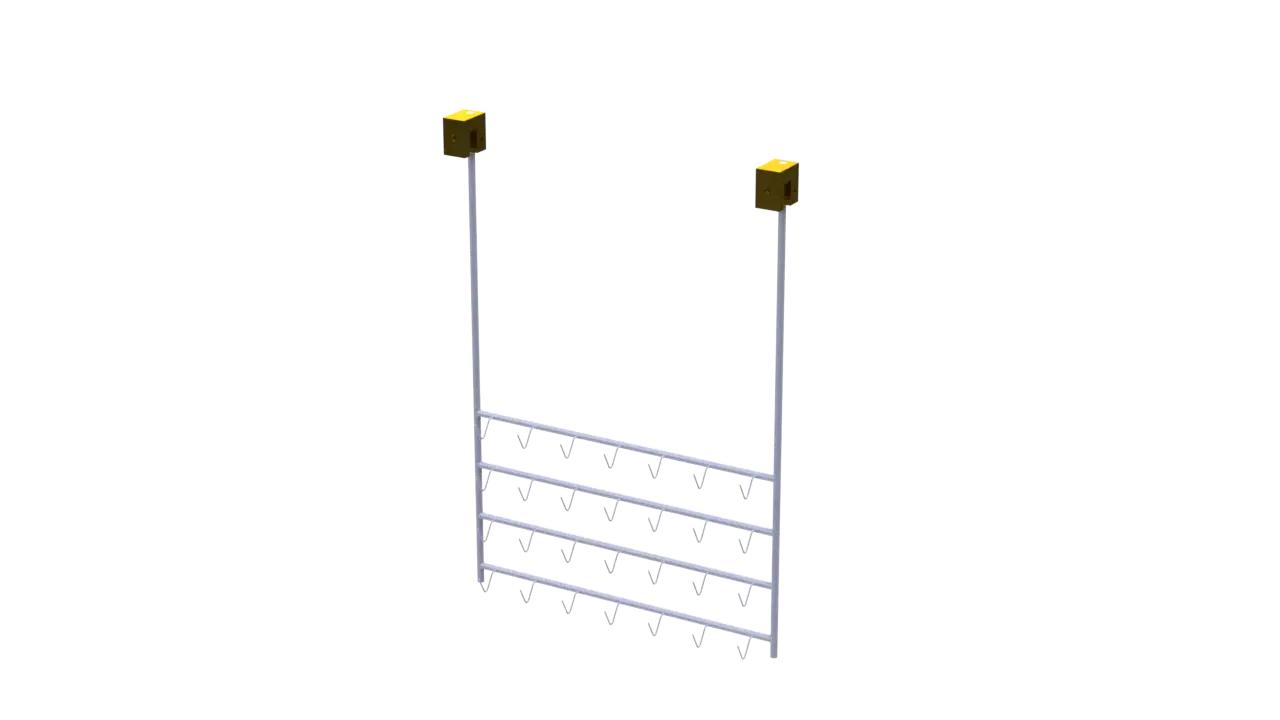

By arranging the anode/cathode frames and spacing, different designs of product carriers and racks can be processed using the anodising process. The Modular structure enables surface treatment in various manufacturing processes – from single to mass production of medical components.

Vibration & circulation

The multidimensional fabric and electrolyte movement ensures the best possible and most homogeneous layer structure. Specially designed movement equipment prevents adhesion and contact points during bulk material processing and individual production.

Cleaning and degreasing of metallic surfaces.

Cleaning and degreasing of metallic surfaces.

Electrochemical processing of the surfaces to strengthen the existing oxide layer.

Additional cleaning and compaction of the titanium surface by hot rinsing.

The most flexible and modular anodizing module in our range of devices for medical components for colour anodizing and grey anodizing. The modular design of the individual modules and additional modules (modular system) enables adaptation to different customer needs and surface requirements. Chemical and electrochemical processing steps for the surface treatment of titanium and titanium alloys can be realized and implemented.

To guarantee a flawless and homogeneous surface finish, we combine the anodizing module with other modules for pre- and post-treatment in a modular system. Optionally designed tank equipment and multiple rinsing technology guarantee reproducible and homogeneous coloring of components made of titanium, titanium alloys and niobium.

Standard tray design:

TITANIUM

Pilot plant

Pre-cleaning module

Pickling module

Anodizing module

Post-treatment module

Internal dimensions

Active tub mm

(HxWxD)

–

Stain tray

350 x 240 x 320

Anodizing tray

350 x 240 x 320

–

Internal dimensions

Flushing units in mm

(HxWxD)

Pedestal/spray sink:

350 x 200 x 310

Pedestal sink

350 x 130 x 310

Pedestal/spray sink:

350 x 200 x 310

Pedestal sink

350 x 130 x 310

Pedestal/spray sink:

350 x 200 x 310

Pedestal sink

350 x 130 x 310

Dual cascade:

350 x 260 x 310

Hot sink:

350 x 200 x 310

Technical data pilot plant

Volume

Optional 20-50L tank volume (standard)

Other sizes on request

Electrical connection

230 V AC (50-60 Hz)

Power consumption

100 W

1500 W

1500 W - 1550 W

800 W

3-5 rows

Various sizes

Various sizes

Extension set

Extension

Option as stand-alone appliance

Spare part

Spare part

Spare part

Output power: max. 12000 Watt

Output current: max. 60A (at 20V)

Output voltage: max. 600V (at 3A)

DATA SHEET RECTIFIER |

Output power: max. 750 Watt

Output current: max. 60A (at 12V)

Output voltage: max. 250V (at 3A)

|

DATA SHEET RECTIFIER |

Thanks to its modular design and expansion options, our titanium colouring system can be tailored precisely to your needs. From a single module to a complete production line. Depending on the process sequence and requirements, you can add further modules, such as a pre-treatment module (pickling, degreasing, ultrasonic cleaning and rinsing) or a post-treatment module (hot rinsing or ultrasonic cleaning). This gives you high process reliability and flexibility in your workflows. This guarantees good conditions for optimum surface results and properties.

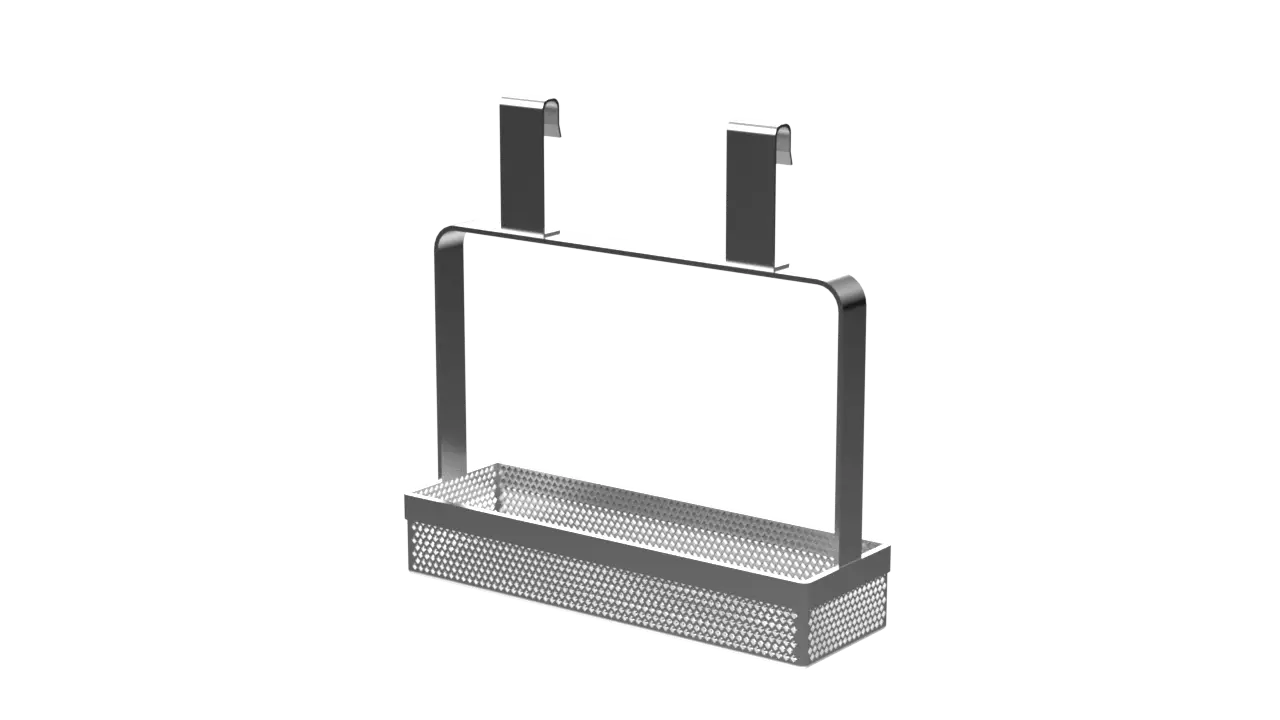

Pre-treatment module after ultrasonic cleaning consisting of: Double cascade and standing/spray rinse with stand and drip tray.

Pickling module consisting of pickling tub with control panel, lid with suction nozzle and various tub fittings (optional), pedestal sink, pedestal/spray sink with underframe and drip tray.

Post-treatment module after pickling/anodizing process, consisting of: Double cascade, hot rinse with underframe, drip tray and control panel.

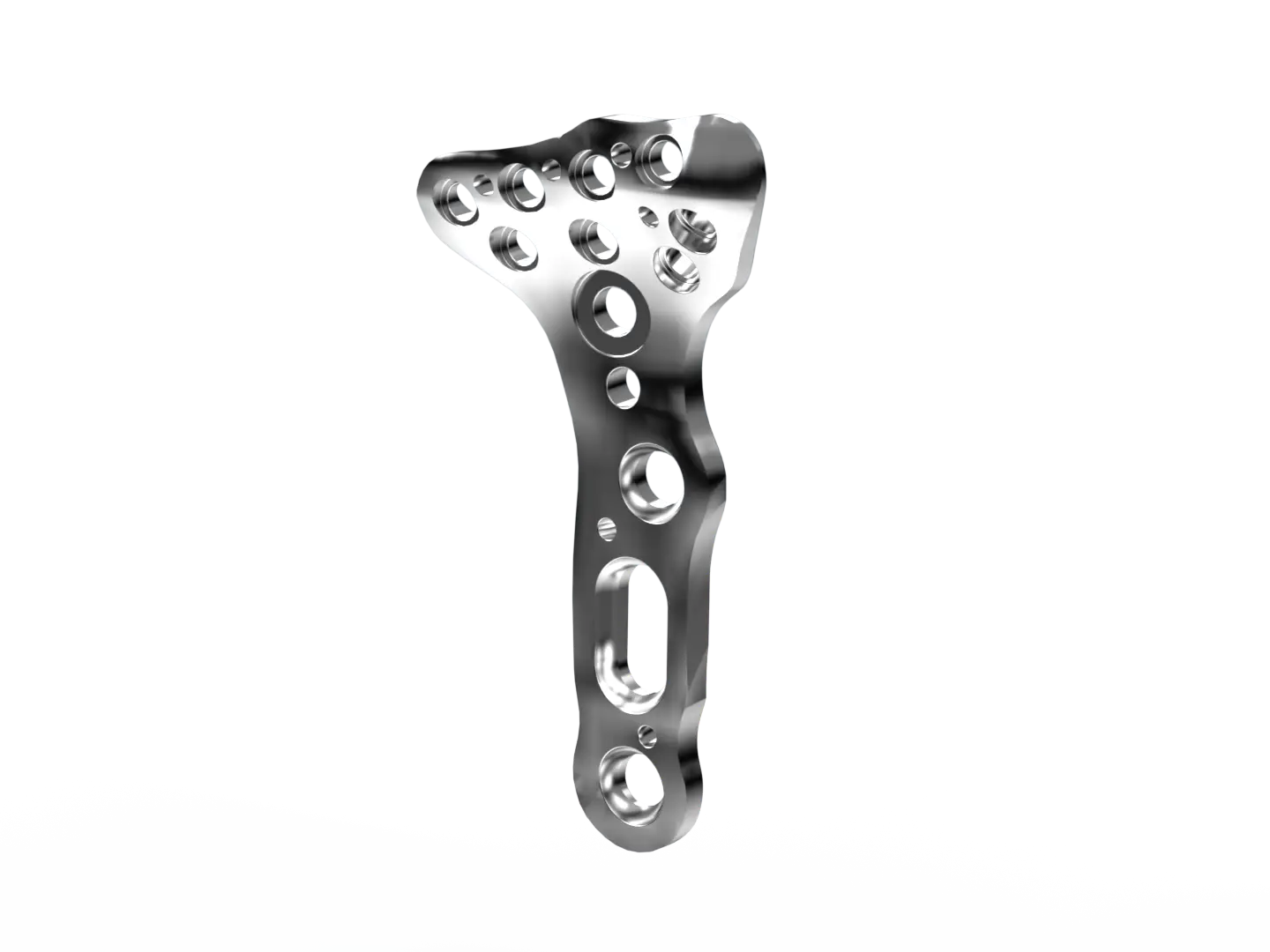

Medical parts or components made of titanium or titanium alloys are electrochemically anodized with special aqueous electrolytes. The result is a thin, firmly adhering titanium oxide layer that appears colored due to the superimposition of light waves (interference). The color palette of type III anodized surfaces ranges from titanium grey, blue, yellow, magenta to green. The main purpose of anodizing medical parts and components is to improve identification and corrosion protection. The titanium oxide layer has very good electrical insulation and biocompatibility.

In addition to colour anodising, grey anodising (acidic or alkaline) can also be carried out in the plants. Type II grey anodising is preferably used for bone plates, screws and implants. The process produces even greater layer thicknesses and serves to improve corrosion and wear resistance.

Vibrating frame

for even

Surface coating

80 % fewer rejects

More parts per

Anodizing pass

Anodizing of large

and small parts

Your contact to us

Sie sehen gerade einen Platzhalterinhalt von rapidmail. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenMarketing & Sales

You are currently viewing a placeholder content from Accessibility Widget. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information