Subcontracted electroplating

Electroplating as a service

Our consistent customer orientation makes us the ideal partner for optimal surface coating as we particularly focus on individual wishes. The choice of surface treatment reflects the purpose of use, corrosion protection, function and decorative appearance. Using special process techniques, we guarantee an optimal surface finish even for partial coatings and geometrically complicated parts. Finally, in addition to flexibility, speed and top quality, we also offer support and advice for solving technical issues.

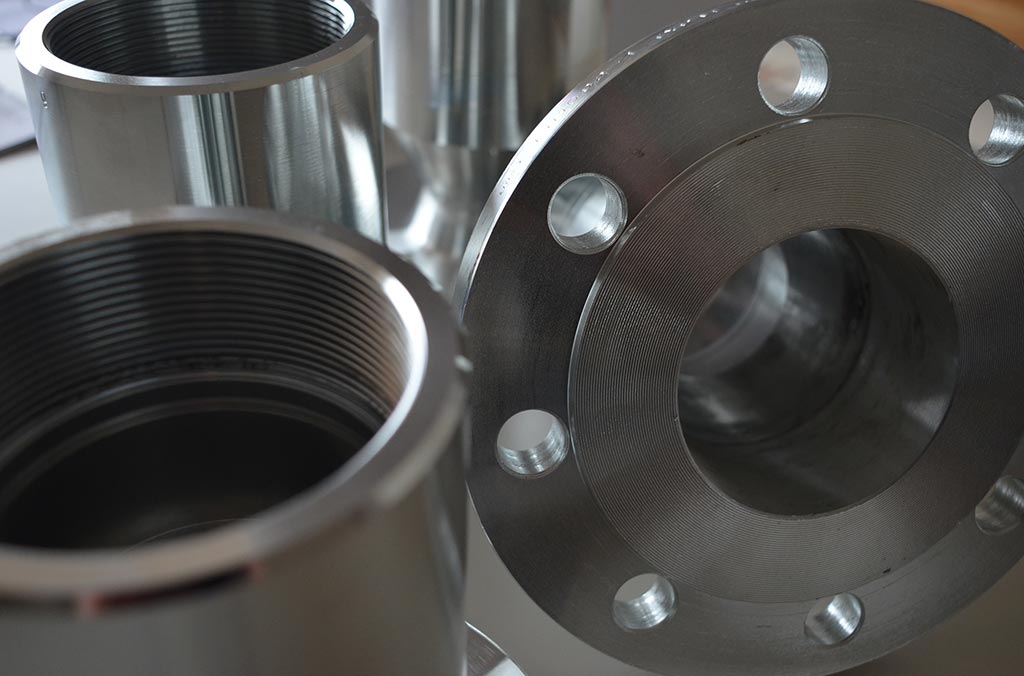

Surface coating of steel parts and non-ferrous metals

We specialize in galvanic surface coating of parts and components. The supplied components can be surface treated as follows:

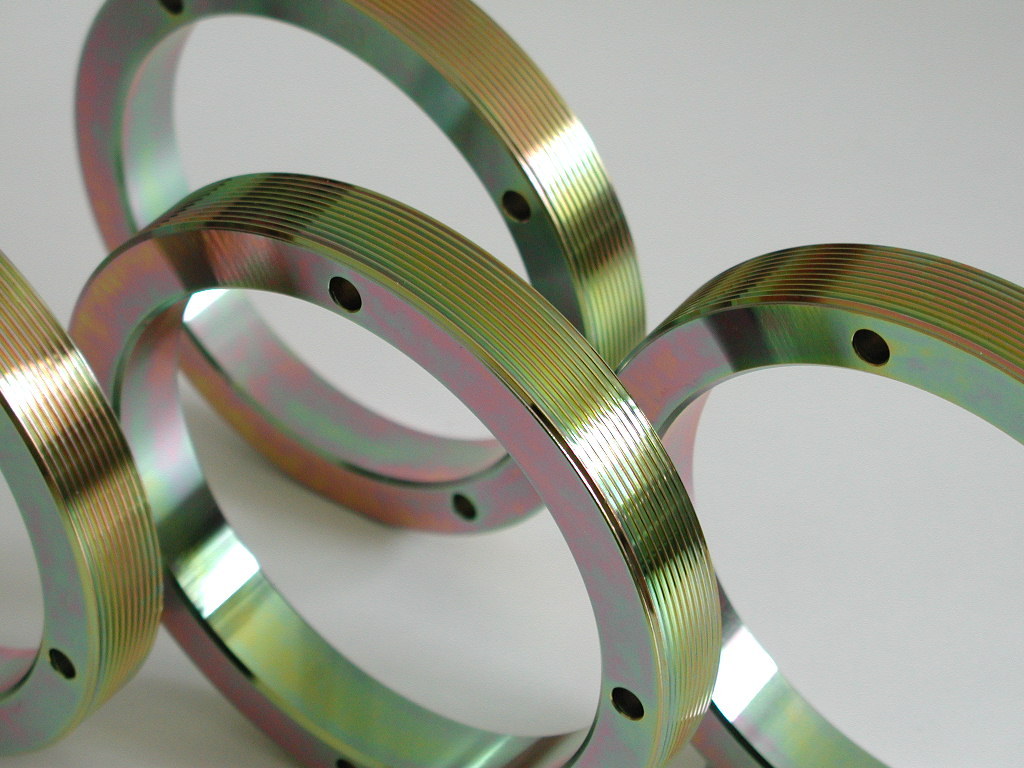

Electrogalvanizing and passivation

Rack goods:

Galvanized according to DIN 50979: Formation of passivation layers in blue (transparent; CrVl-free), black, olive and yellow variants for improving corrosion protection, increasing surface hardness of parts and optical aspects.

Usable rack bath size:

2000 x 350 x 750 mm or 700 x 500 x 1100 mm

Tubes: max. 500 x 1100 mm

Drum goods:

Electrogalvanizing of small parts with a capacity of max. 30 kg

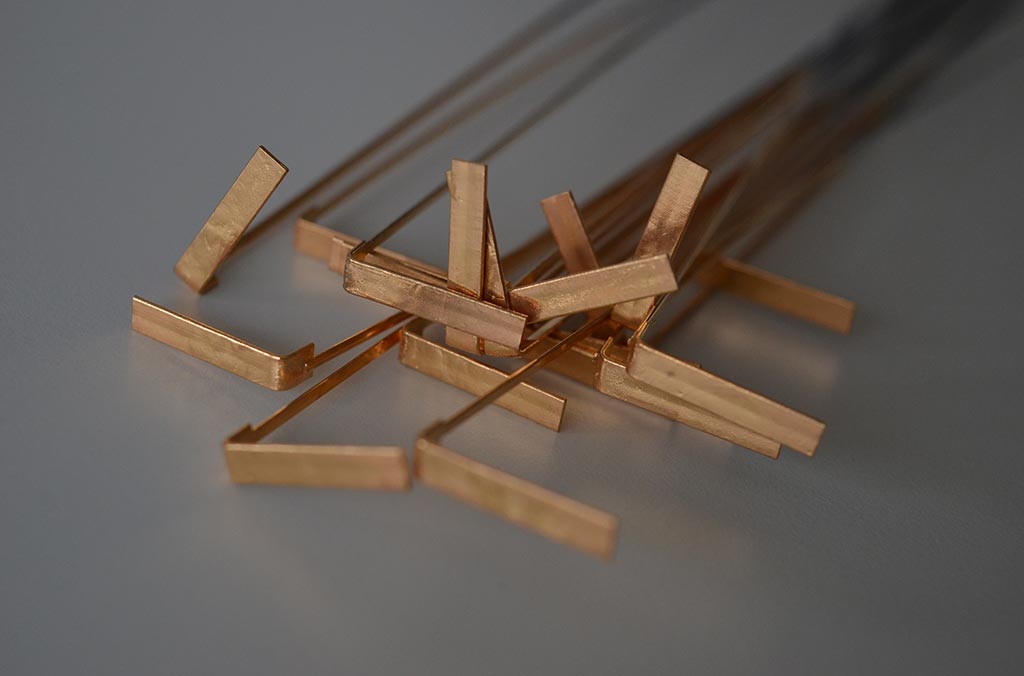

Electrogalvanic tinning

Tin coatings on ferrous materials and copper materials according to DIN 50965 - Cu/SnMax. rack size: 450 x 400 mm

Degreasing of components

Electrolytic degreasing of stainless-steel components on request

Special solutions

Surface coating of small parts and small series on request- Pickling, etching, anodizing of titanium an titanium alloys

- Electrochemical polishing and deburring (electropolishing) of titanium, titanium alloys and stainless steel

- Chemical polishing and deburring of stainless steel

- Passivation

- Diverse chemical surface treatment (e.g., pickling, etching)

- Diverse electrochemical surfaces (decorative and functional)

- Diverse currentless surface treatment (e.g., chemical Ni/Au, chemical Sn)