Manual system for the surface finishing of medical components

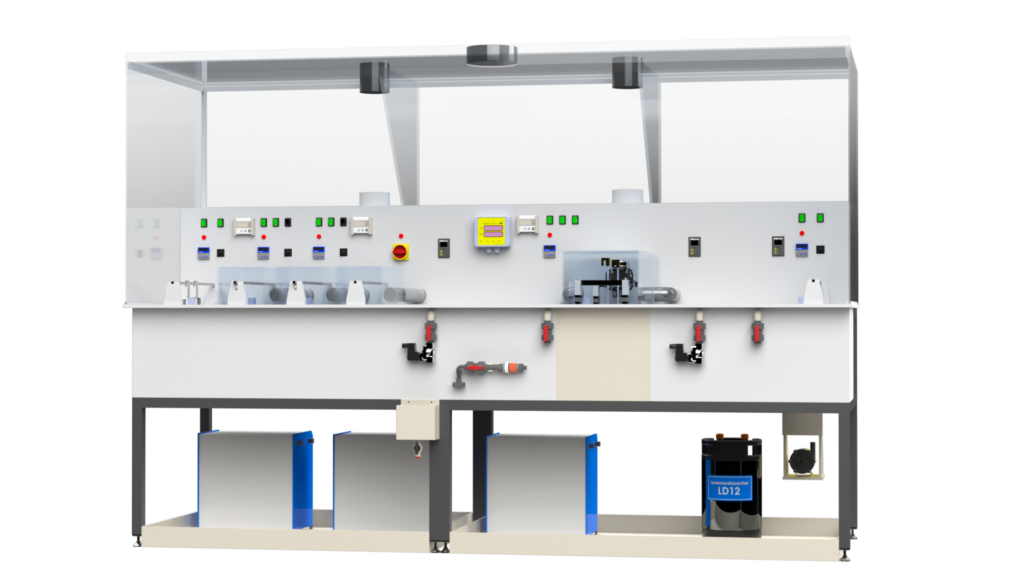

Galvaniklinie für die Bearbeitung von Titan, Titanlegierung und Niob. Integrierte Spültechnik und Bedienpanel. Zu- und Ablaufführung von Frisch- und Spülwasser und Absaugvorrichtung. Optionale Zusatzkomponenten nach Kundenwunsch.

Electroplating line for processing titanium, titanium alloys and niobium. Integrated

Flushing technology and control panel. Fresh and rinse water supply and drainage

and suction device. Optional additional components according to customer requirements.

Versions:

Standard tray design:

Output power: max. 12000 Watt

Output current: max. 60A (at 20V)

Output voltage: max. 600V (at 3A)

DATA SHEET RECTIFIER |

Output power: max. 750 Watt

Output current: max. 60A (at 12V)

Output voltage: max. 250V (at 3A)

|

DATA SHEET RECTIFIER |

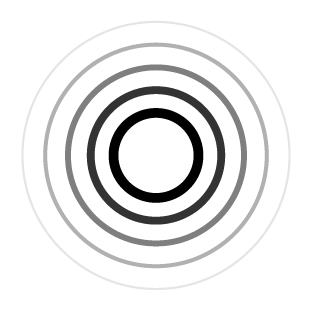

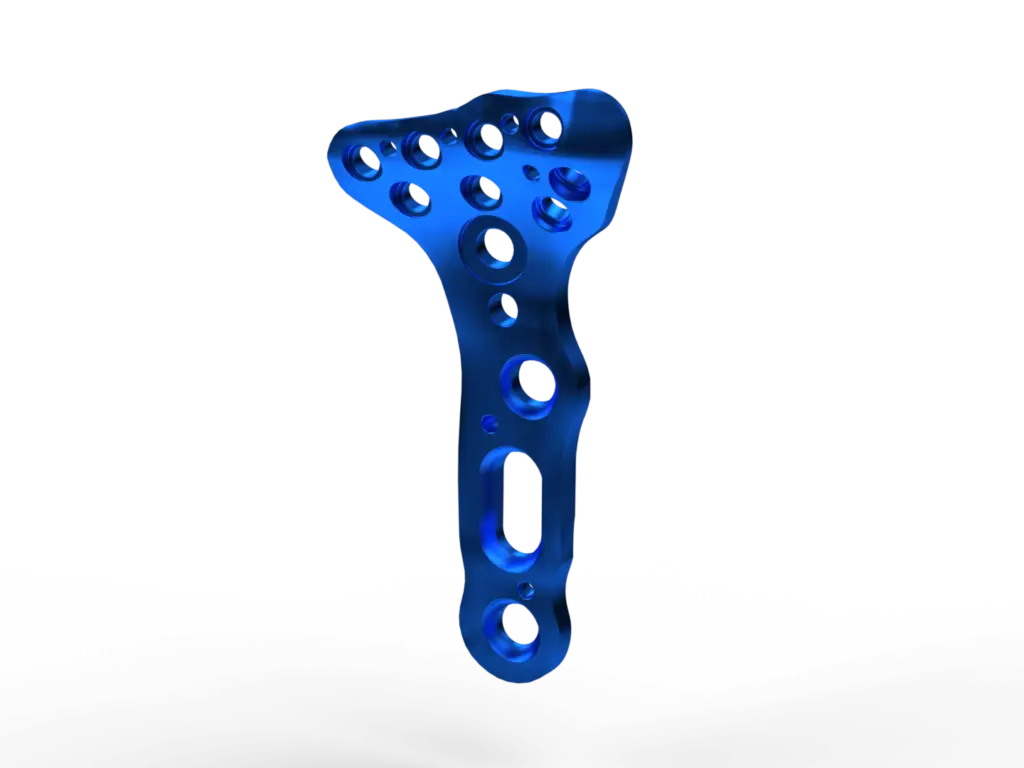

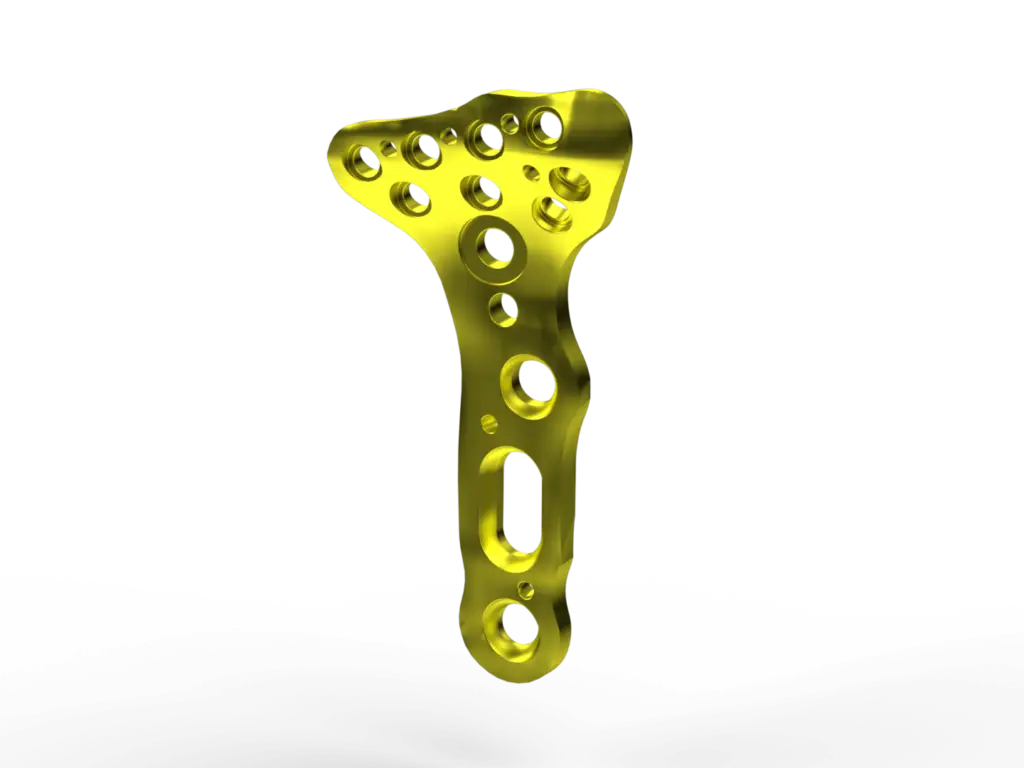

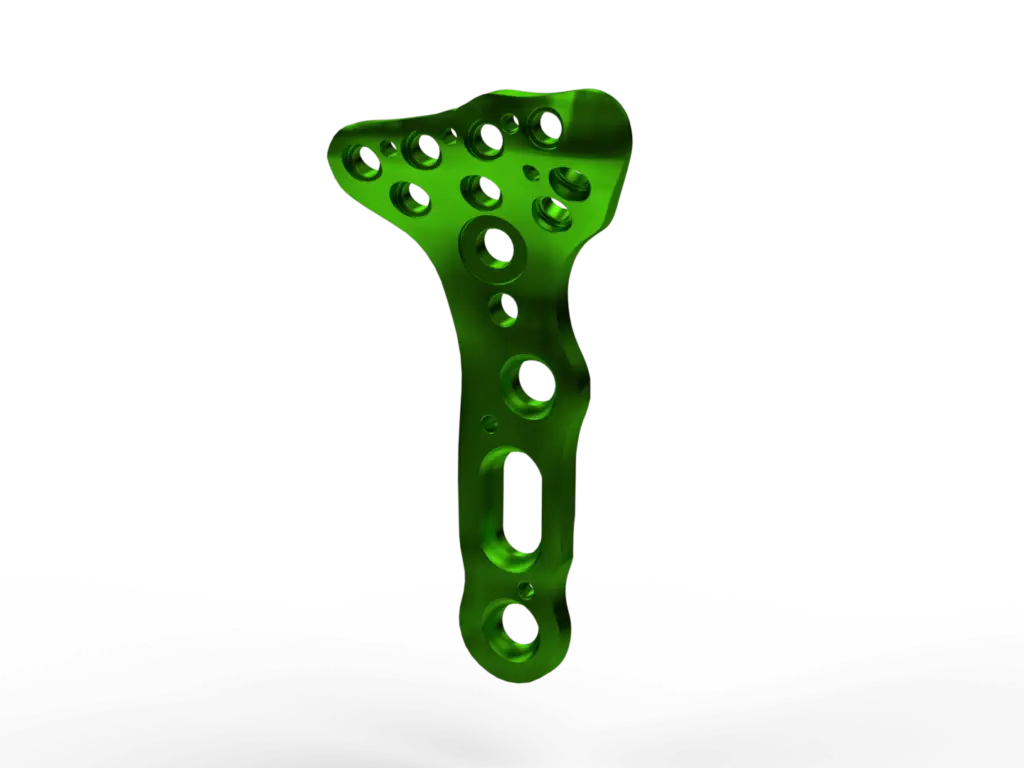

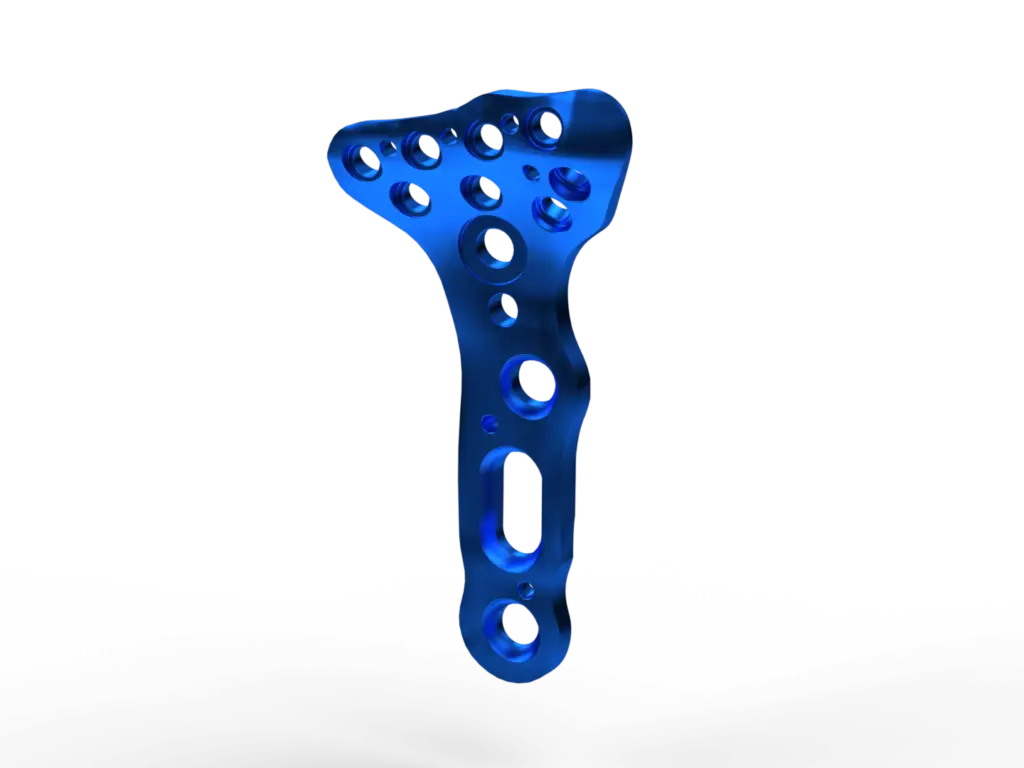

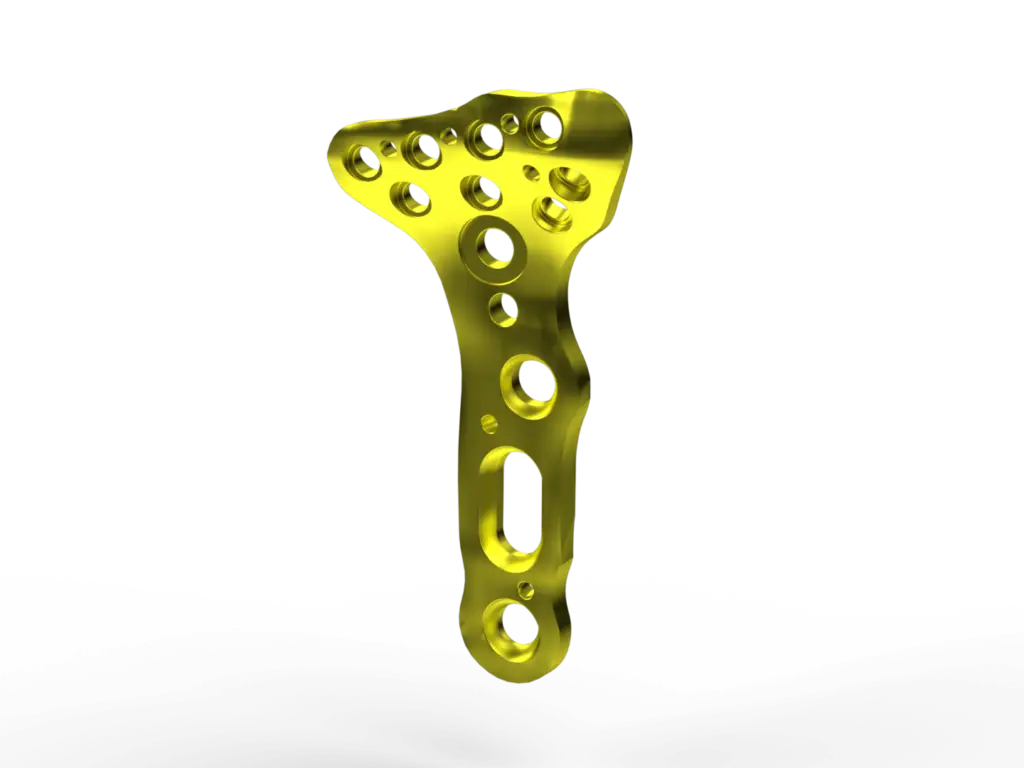

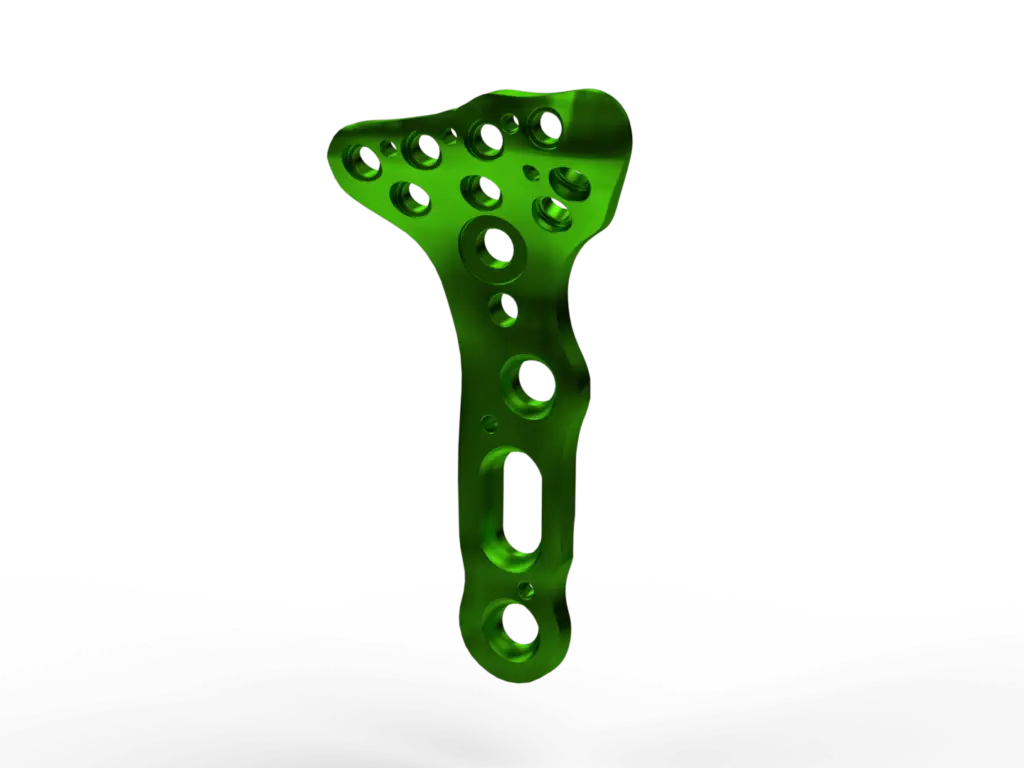

Medical parts or components made of titanium or titanium alloys are electrochemically anodized with special aqueous electrolytes. The result is a thin, firmly adhering titanium oxide layer that appears colored due to the superimposition of light waves (interference). The color palette of type III anodized surfaces ranges from titanium grey, blue, yellow, magenta to green. The main purpose of anodizing medical parts and components is to improve identification and corrosion protection. The titanium oxide layer has very good electrical insulation and biocompatibility

In addition to colour anodizing, grey anodizing (acidic or alkaline) can also be carried out in the systems. Type II grey anodizing is preferably used for bone plates, bone screws and bone implants. The process produces even thicker coatings and serves to improve corrosion and wear resistance.

Please contact us using our inquiry form or give us a call.

Do you have questions about our systems? Please contact us directly.

Would you like a quote?

Write us an

e-mail

Please use our contact form. We will get in touch with you.

Birkenstraße 13 | 97892 Kreuzwertheim | Germany

We inform you optionally about:

*Log in with your e-mail address

© 2025 Walter Lemmen GmbH

Medical parts or components made of titanium or titanium alloys are electrochemically anodized with special aqueous electrolytes. The result is a thin, firmly adhering titanium oxide layer that appears colored due to the superimposition of light waves (interference). The color palette of type III anodized surfaces ranges from titanium grey, blue, yellow, magenta to green. The main purpose of anodizing medical parts and components is to improve identification and corrosion protection. The titanium oxide layer has very good electrical insulation and biocompatibility

In addition to colour anodizing, grey anodizing (acidic or alkaline) can also be carried out in the systems. Type II grey anodizing is preferably used for bone plates, bone screws and bone implants. The process produces even thicker coatings and serves to improve corrosion and wear resistance.

Electrochemical polishing (electropolishing) and deburring of stainless steel significantly improves the properties of the metallic surface, which has a positive effect on the durability of the individual components. Electropolishing is an electrochemical process for surface removal. The removal is carried out with special aqueous solutions using electricity in the micro range and produces a smooth and shiny surface.

Your contact to us

Marketing & Sales