Business areas

Exposure devices & film production

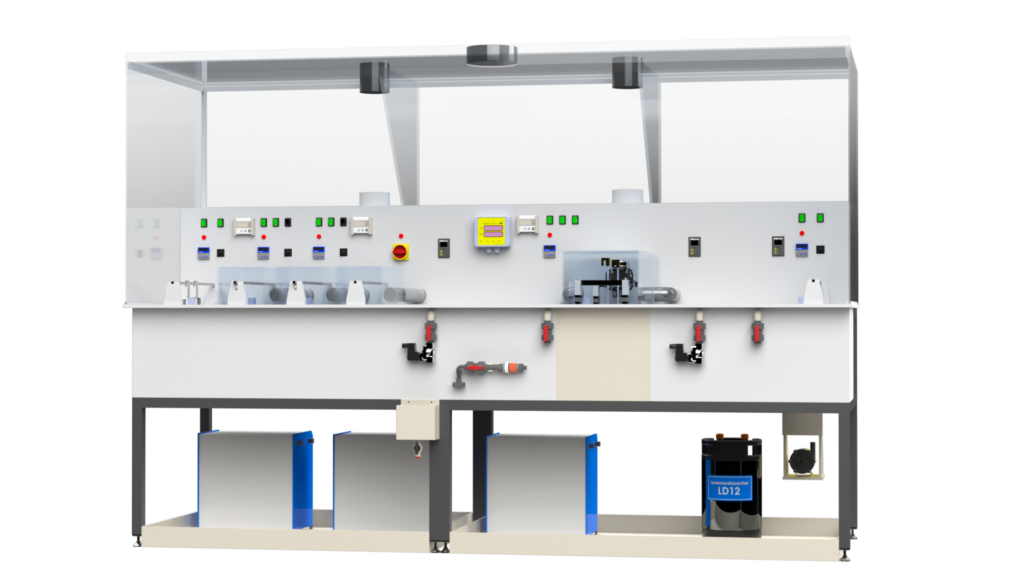

Developer / Etcher / Stripper

Through-hole plating systems

End surface, galvanized & electroless

Multilayer presses

Cutting systems / brushing systems

Drilling & milling machines

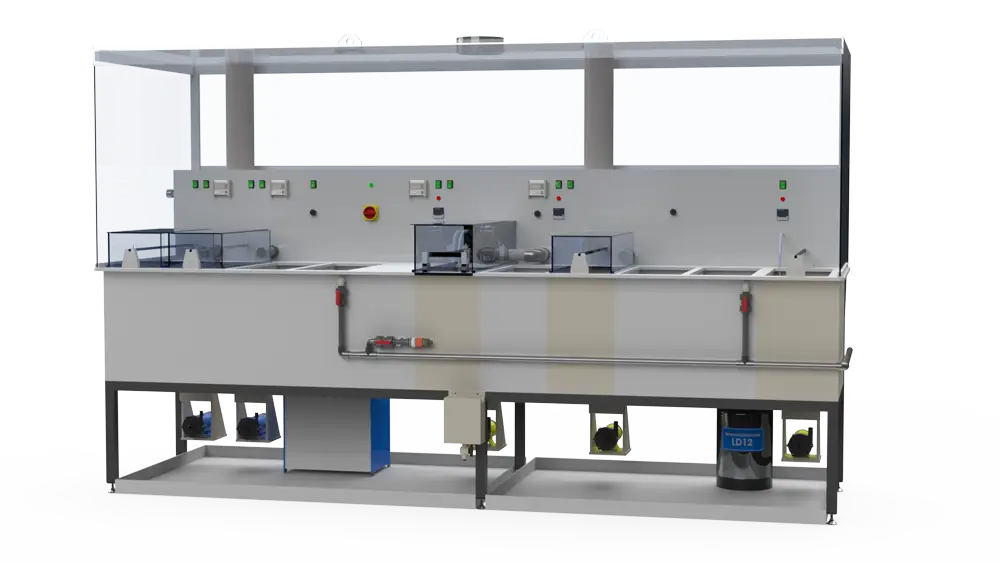

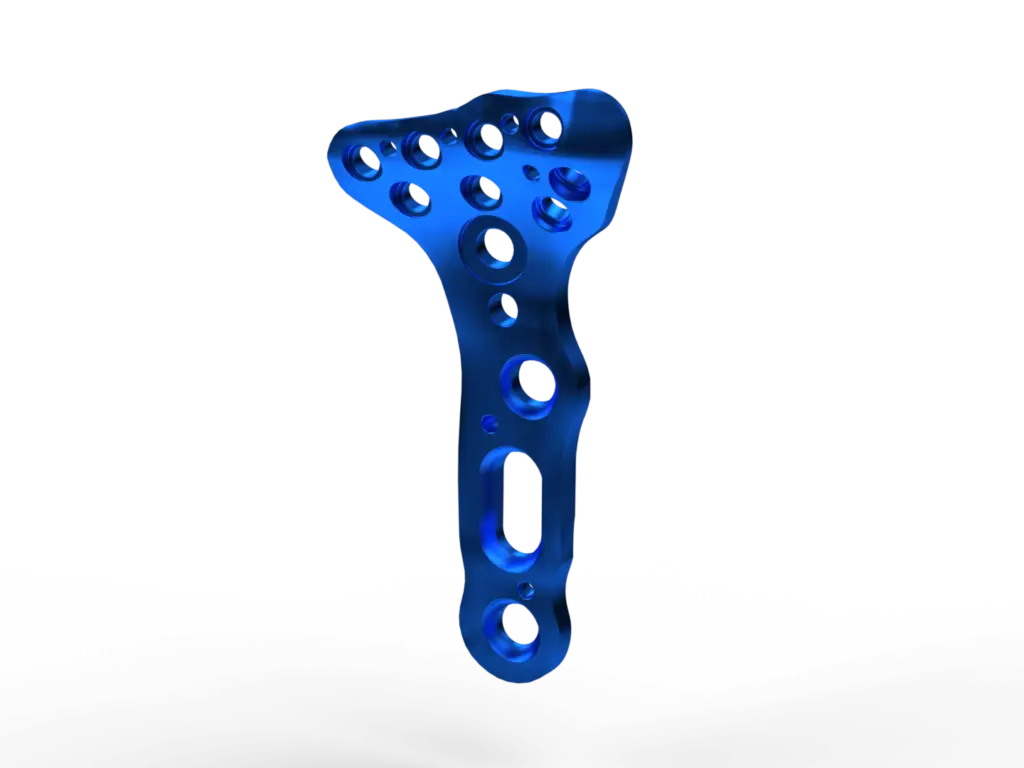

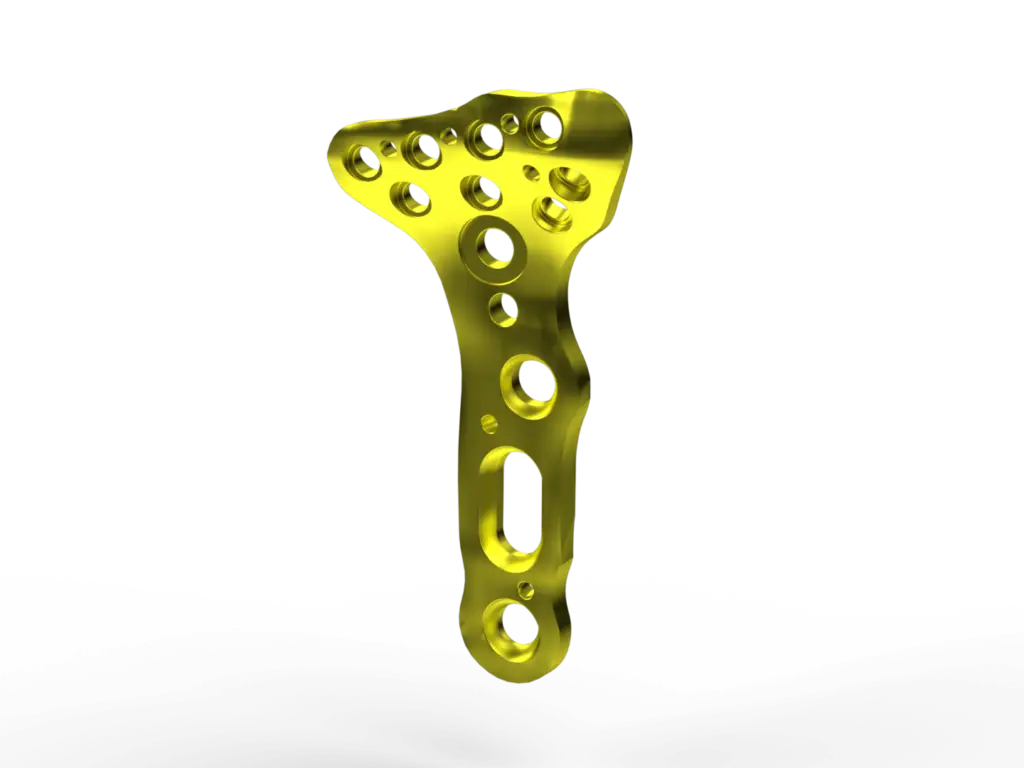

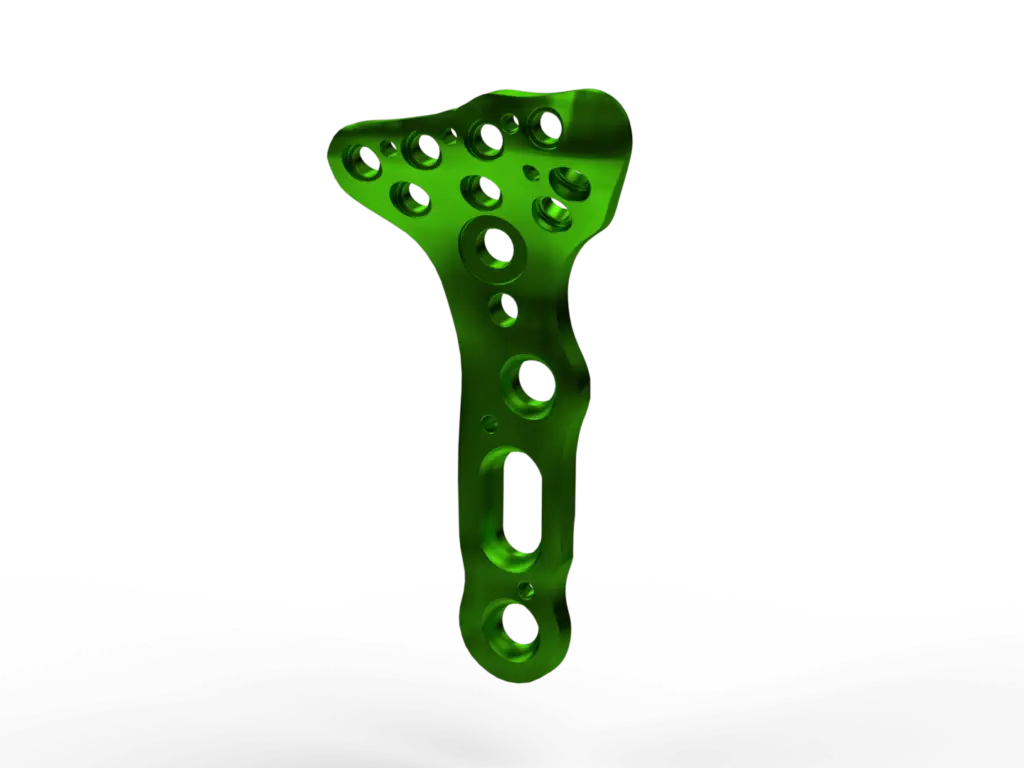

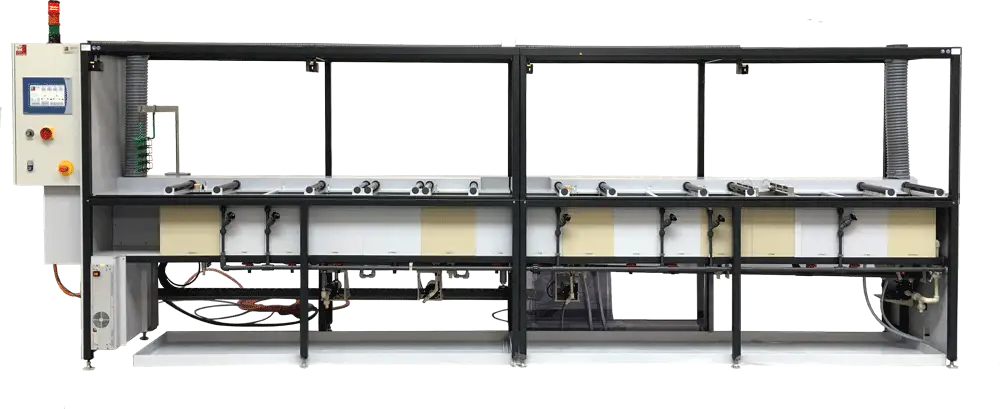

Manual electroplating systems

Table electroplating

Manual electroplating systems

Rotation unit

Ion exchange systems IONEX

Metal recovery

Filter units

Contact us

Direct contact

Write us an e-mail or give us a call.

-

Walter Lemmen GmbH

Birkenstaße 13

D-97892 Kreuzwertheim - + 49 (0) 93 42-240977-0

- + 49 (0) 93 42-240977-29

- info@walterlemmen.de

Für weitere Informationen und technische Auskünfte stehen wir Ihnen selbstverständlich auch persönlich zur Verfügung:

Sales/Marketing

Dipl.-Betrw. (FH) Tanja Lemmen

E-Mail: tanja@walterlemmen.de

Technical information

Dipl. Ing. Walter Lemmen

E-Mail: info@walterlemmen.de

Dipl. Ing. Dieter Lemmen

E-Mail: info@walterlemmen.de

Dates

ZVO Surface Days Berlin 2025

Congress for electroplating and surface technology

- Sep 24- 26, 2025

- Booth no. 54

Productronica Munich 2025

World's leading trade fair for the development and production of electronics

- Nov 18- 21, 2025

Surface Technology Stuttgart 2026

International Trade Fair for Surfaces & Coatings

- June 04- 06, 2026

STAY UP TO DATE

Walter Lemmen GmbH