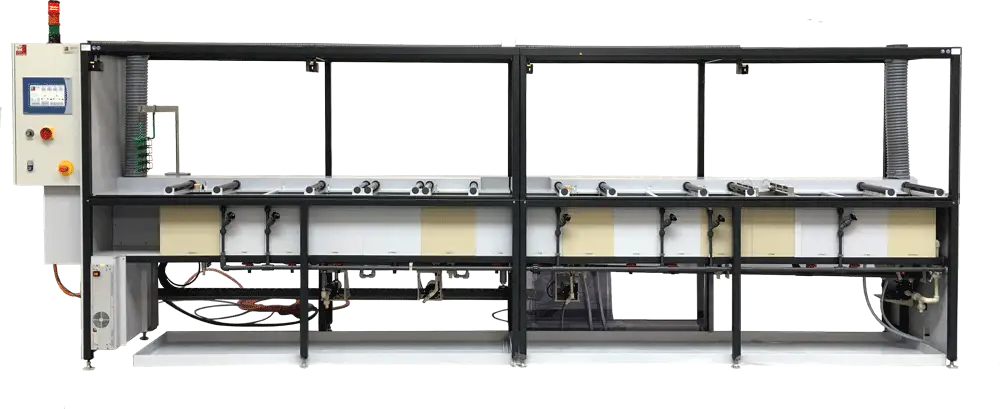

Automated electroplating system with PLC and linear traversing system

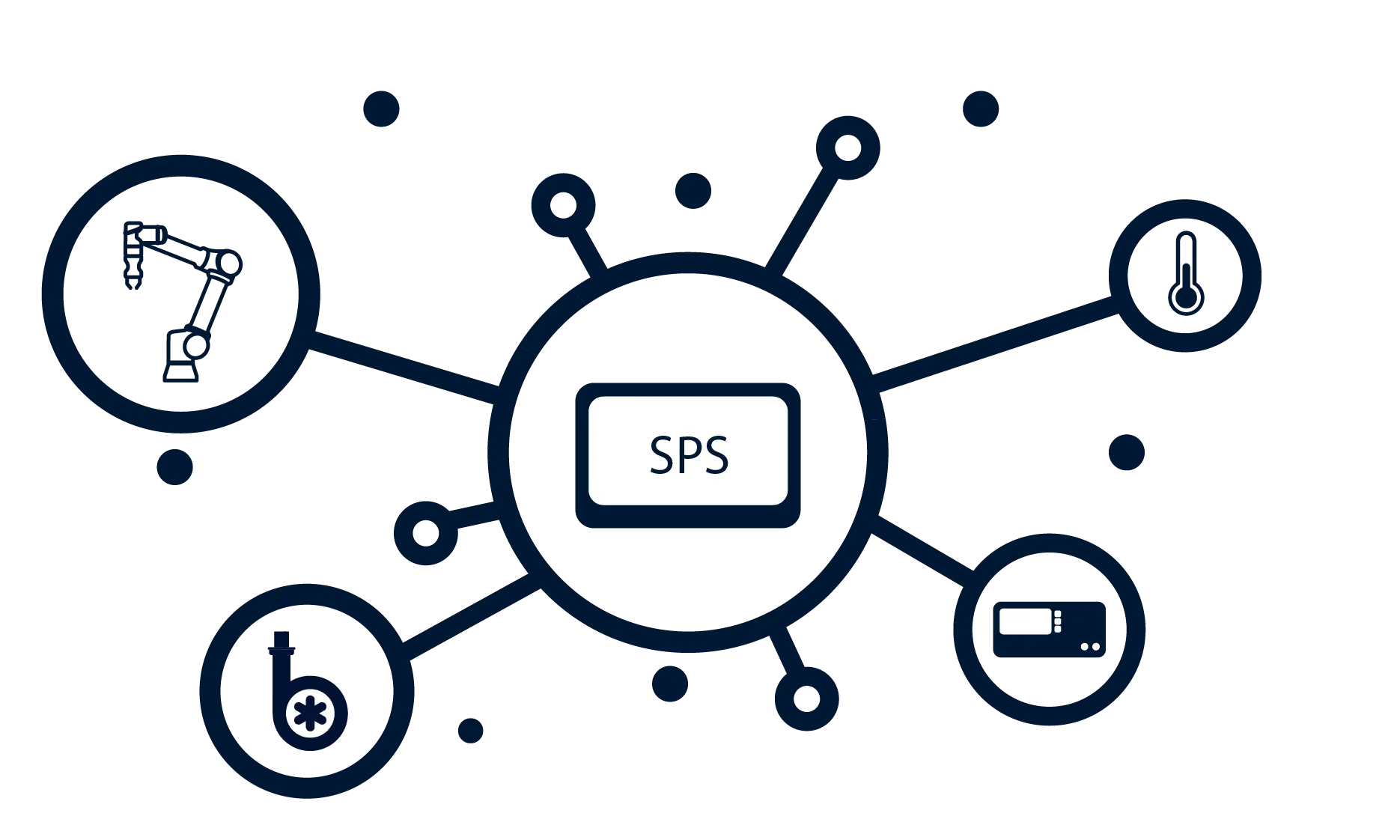

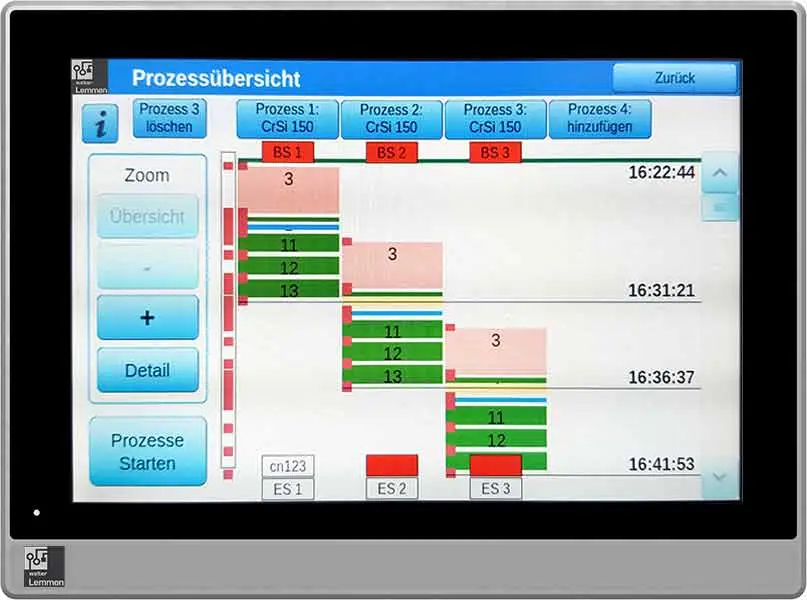

The COMPACTA SPS optimizes and automates chemical and electrochemical process sequences in the

electroplating technology. It offers numerous control options & setting parameters for a customer-specific process sequence. Thanks to automation, consistent surface results can be achieved on a recurring basis.

Mit der Galvaniklinie COMPACTA SPS können Auf- und Abwärtsbewegungen auf dem Liniearverfahrsystem individuell programmiert und durchgeführt werden. Die Prozessabläufe erfolgen sequenziell oder optional im Parallelbetrieb.

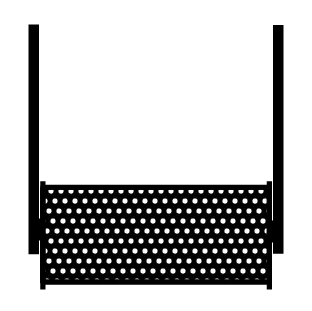

The rope system developed in-house for transporting the product carriers is made of chemical-resistant polypropylene and is therefore suitable for all chemical and electrochemical electrolyte applications.

The COMPACTA SPS is multifunctional and can be used for drum, basket and rack goods. The maximum payload per container is approx. 10 kg. The basin volume and other equipment features can be customized.

Versions:

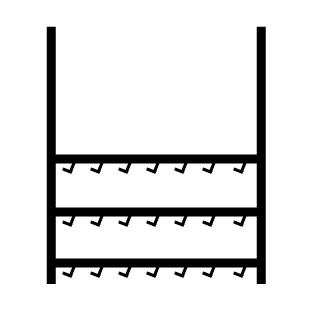

Standard tray design:

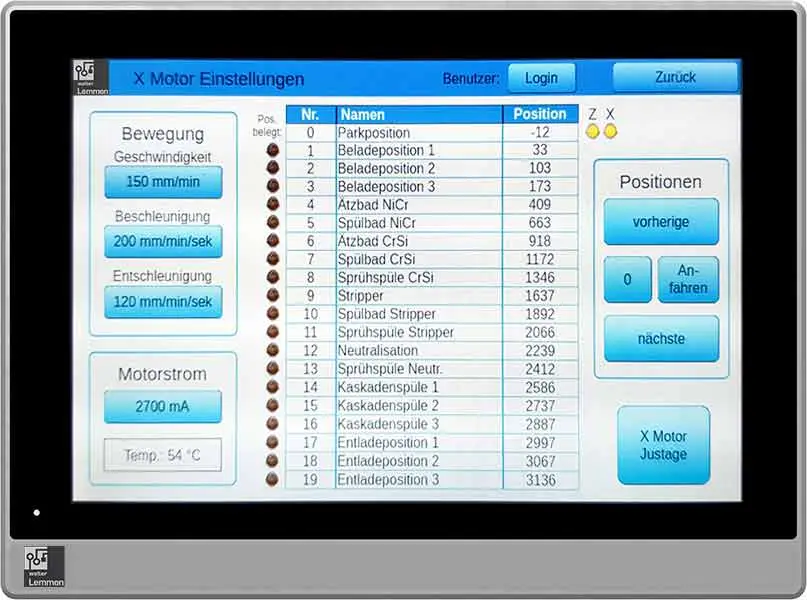

The following bath parameters can be individually programmed using the PLC control:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Wir planen, entwickeln und bauen manuell geführte oder automatisierte Anlagen individuell nach Ihrem Oberflächenprozess.

Please contact us using our inquiry form or give us a call.

Do you have questions about our systems? Please contact us directly.

Would you like a quote?

Write us an

e-mail

Please use our contact form. We will get in touch with you.

Birkenstraße 13 | 97892 Kreuzwertheim | Germany

We inform you optionally about:

*Log in with your e-mail address

© 2025 Walter Lemmen GmbH

Your contact to us

Marketing & Sales